|

|

- Search

| J. Korean Soc. Hazard Mitig. > Volume 19(1); 2019 > Article |

|

Abstract

This study investigated the feasibility of applying ultra-high-performance concrete (UHPC) on the outer containment of a liquefied natural gas storage tank to improve its safety and durability. For this purpose, normal concrete (NC) and UHPC with three different straight steel fiber specimens (i.e., S65, S97.5, and S100) were fabricated and tested under a four-point bending load at three different conditions (i.e., ambient, cryogenic-AC, and cryogenic-WC) before and after cryogenic exposure to evaluate the effect of cryogenic temperature. Microscopic observation and scanning electron microscopy-energy dispersive X-ray spectroscopy (SEM-EDX) analysis were performed to determine cracking and self-healing behavior. The test results indicated that UHPC provided better resistance to crack formation than NC at cryogenic temperature. Moreover, UHPC with the S65 fiber showed the best performance at cryogenic temperature in terms of flexural performance and self-healing capacity. The SEM-EDX analysis confirmed that, after 28 days of water curing, the crack-filling materials were calcium carbonate (CaCO3).

ýÜöýºÇ

Ù│© ýù░ÛÁ¼ýùÉýä£Ùèö LNG ýáÇý×ÑÝâ▒Ýü¼ýØÿ ýòêýáäýä▒ Ù░Å Ùé┤ÛÁ¼ýä▒ýØä ÝûÑýâüýï£ÝéñÛ©░ ý£äÝò┤ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©Ùí£ Û▒┤ýäñÙÉÿÙèö ýÖ©ýí░ýùÉ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©(UHPC, Ultra-High-Performance Concrete)ÙÑ╝ ýáüýÜ®ÝòÿÛ©░ ý£äÝò£ ýù░ÛÁ¼ÙÑ╝ ýºäÝûëÝòÿýÿÇÙïñ. ýØ┤ÙÑ╝ ý£äÝò┤ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ÙÑ╝ ýá£ý×æÝòÿýÿÇý£╝Ù®░, ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û░òýä¼ý£á ýóàÙÑÿýùÉ Ùö░ÙÑ© ý░¿ýØ┤ÙÑ╝ ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò┤ ýä© ýóàÙÑÿýØÿ ýØ╝ý×ÉÝÿò Û░òýä¼ý£á(S65, S97.5, S100)ÙÑ╝ ýé¼ýÜ®ÝòÿýÿÇÙïñ. ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© ÛÀáýù┤Û▒░ÙÅÖ Ù░Šݣ¿ ýä▒ÙèÑ, ý×ÉÛ©░ý╣ÿý£á Ýè╣ýä▒ýØä ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò┤ 4ýáÉ Ý£¿ ýïñÝùÿ Ù░Å Û┤æÝòÖÝÿäÙ»©Û▓¢ Û┤Çý░░, SEM-EDX ÙÂäýäØýØä ýïñýï£ÝòÿýÿÇÙïñ. ýú╝ÙÉ£ Û▓░Û│╝Ùí£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© ÛÀáýù┤ýáÇÝò¡ýä▒ÙèÑýØ┤ Ùø░ýû┤Ùé¿ýØä ÝÖòýØ©ÝòÿýÿÇý£╝Ù®░, ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýò£ ýåÉýâüýØÇ ýÁ£ÙîÇ 28ýØ╝ýØÿ ýêÿýñæýûæýâØýØä ÝåÁÝò┤ ÝÜîÙ│ÁÙÉá ýêÿ ý×êýØîýØä ÝÖòýØ©ÝòÿýÿÇÙïñ. ÙÿÉÝò£ ýêÿýñæýûæýâØýØä ÝåÁÝò£ ý×ÉÛ©░ý╣ÿý£á Ù¼╝ýºêýØÇ Ýâäýé░ý╣╝ýèÿ(CaCO3) ý×äýØä ÝÖòýØ©ÝòÿýÿÇÙïñ.

ýòíÝÖöý▓£ýù░Û░Çýèñ(Liquefied Natural Gas, LNG)Ùèö ý×Éýù░ýùÉ Û©░ý▓┤ ýâüÝâ£Ùí£ ýí┤ý×¼ÝòÿÙèö ý▓£ýù░Û░ÇýèñÙÑ╝ ýò¢ ÔÇô162 ┬░CÙí£ ÙâëÛ░üÝòÿýù¼ ÙÂÇÝö╝ÙÑ╝ 600ÙÂäýØÿ 1 ýêÿýñÇý£╝Ùí£ Û░Éýåîýï£ý╝£ ýÜ┤Ù░ÿýØ┤Ùéÿ ýáÇý×ÑýùÉ ýÜ®ýØ┤ÝòÿÙÅäÙíØ ÙºîÙôá ýù░ÙúîýØ┤Ùïñ. ÙÿÉÝò£ ýäØý£áÙéÿ ýäØÝâä Ùô▒ýØÿ ÙïñÙÑ© ÝÖöýäØýù░ÙúîýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî CO2 Ù░░ý£كëýØ┤ ýáüýû┤ ý╣£ÝÖÿÛ▓¢ ÝÖöýäØ ýù░ÙúîÙí£ ýÀ¿Û©ëÙ░øÛ│á ý×êÙïñ. ÙÿÉÝò£ 2018Ùàä Û©░ýñÇý£╝Ùí£ ýáòÙÂÇÙèö ýùÉÙäêýºÇýáäÝÖÿ ýáòý▒àýØä ÙÆÀÙ░øý╣¿ÝòÿÛ©░ ý£äÝò┤ ÔÇÿýᣠ13ý░¿ ý×ÑÛ©░ ý▓£ýù░Û░Çýèñ ýêÿÛ©ëÛ│äÝÜìÔÇÖýØä ÝåÁÝò┤ ÝûÑÝøä 13ÙàäÛ░ä ýòíÝÖöý▓£ýù░Û░Çýèñ ÙÅäý×àÙƒëýØä ÙîÇÝÅ¡ ÙèÿÙª¼Û│á ýáÇý×ÑÝâ▒Ýü¼ 10Û©░ÙÑ╝ ýÂöÛ░Ç Û▒┤ýäñ ÝòÿÙèö Ùô▒ ýò×ý£╝Ùí£ ýòíÝÖöý▓£ýù░Û░ÇýèñýØÿ ýñæýÜöýä▒ýØÇ ÙìöýÜ▒ ÙîÇÙæÉÙÉá Û▓âý£╝Ùí£ Ù│┤ýØ©Ùïñ.

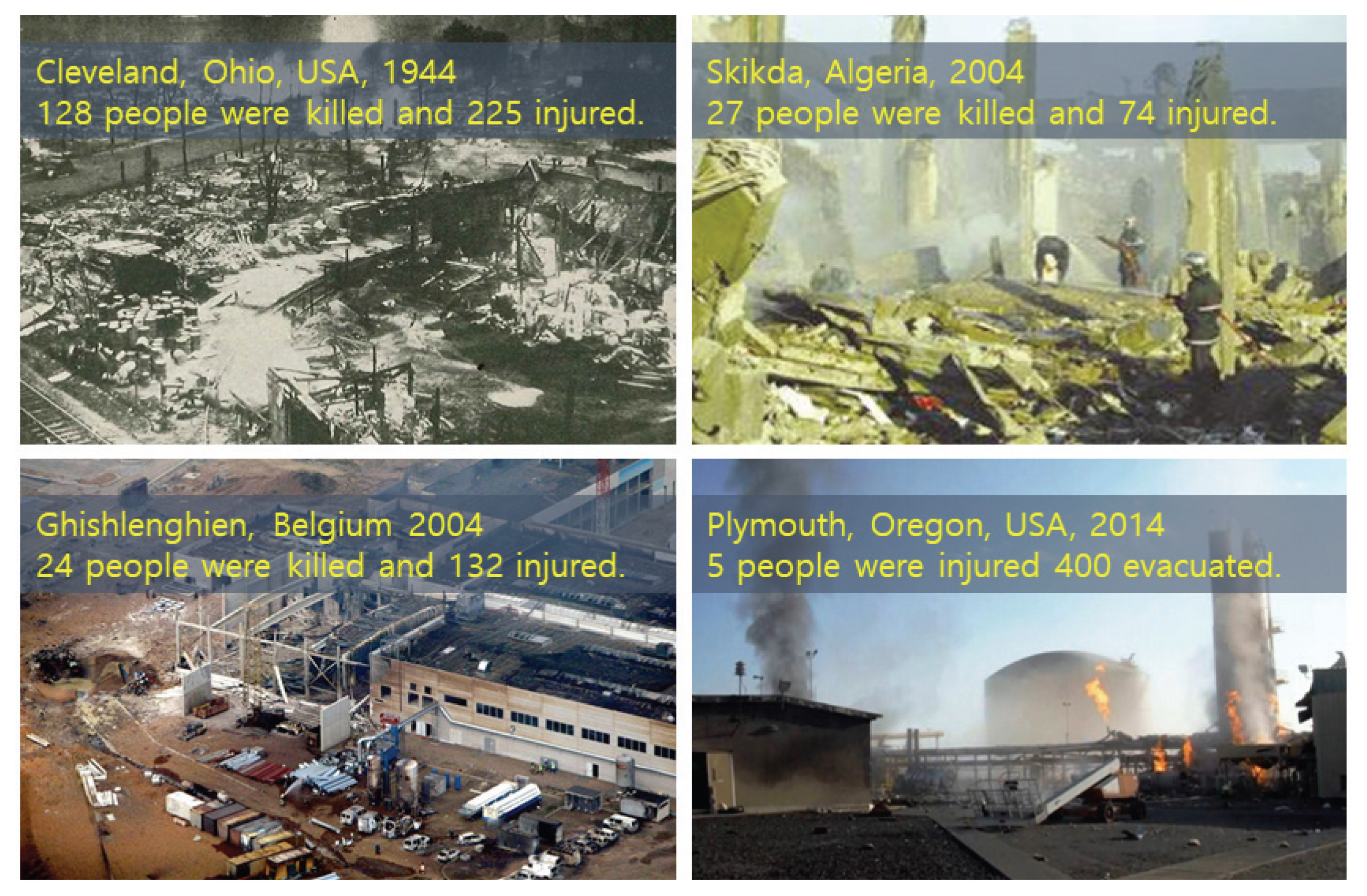

ÛÀ©Ùƒ¼Ùéÿ ýòíÝÖöý▓£ýù░Û░ÇýèñÙèö Û░Çýù░ýä▒ Ù░Å Ù¼┤ýâëÔïàÙ¼┤ýÀ¿ýØÿ Ýè╣ýä▒ýØä Û░ÇýºÇÛ│á ý×êýû┤ Û©░ÝÖöÝòÿýù¼ ÙîÇÛ©░ ýñæýùÉ Ùêäý£ÙÉÿýùêýØä Ùòî Ùêäý£ýØä ýòîýòäý░¿Ùª¼Û©░ Ý×ÿÙôñÙ®░, ÝÅ¡Ù░£Û│╝ ÝÖöýù╝ Ùô▒ Ýü░ ýé¼Û│áÙí£ ýØ┤ýû┤ýºê Û▓¢ýÜ░ ÙîÇÝÿòýة٬àÝö╝Ýò┤Û░Ç Ù░£ýâØÝòá ýêÿ ý×êÛ©░ ÙòîÙ¼©ýùÉ ýáÇý×Ñ Ù░Å ýêÿýåí Ùô▒ ýÀ¿Û©ëýùÉ ÙºñýÜ░ Ýü░ ýú╝ýØÿÙÑ╝ ÝòäýÜöÙí£ Ýò£Ùïñ. ýØ┤Ùƒ¼Ýò£ ÙîÇÝÿòýòêýáäýé¼Û│áýØÿ ýïñÙíÇÙí£ 1944ÙàäýùÉ Ù░£ýâØÝò£ Ù»©ÛÁ¡ Ýü┤Ùª¼Ù©öÙ×£Ùô£ ýé¼Û│áýÖÇ 2004ÙàäýùÉ Ù░£ýâØÝò£ ýòîýá£Ùª¼ ýèñÝéÑÙïñ ýé¼Û│á, 2004ÙàäýùÉ Ù░£ýâØÝò£ Ù▓¿Û©░ýùÉ Û©░ýèñÙáØÝÿá ýé¼Û│á, 2014ÙàäýùÉ Ù░£ýâØÝò£ Ù»©ÛÁ¡ ýÿñÙª¼Û▒┤ ýé¼Û│áÛ░Ç ý×êÙïñ. Ù»©ÛÁ¡ Ýü┤Ùª¼Ù©öÙ×£Ùô£ ýé¼Û│áÙèö LNG ýáÇý×ÑÝâ▒Ýü¼ýØÿ ÝîîÛ┤┤ Ù░Å ÛÀáýù┤Ùí£ ýØ©Ýò┤ LNGÛ░Ç ýú╝Ù│Ç ÙÅäÙí£Û╣îýºÇ ý£áý£ÙÉÿÙ®░ ÝÅ¡Ù░£Ùí£ ýØ┤ýû┤ýá© 131Ù¬àýØÿ ýé¼ÙºØý×ÉýÖÇ 225Ù¬àýØÿ ÙÂÇýâüý×ÉÛ░Ç Ù░£ýâØÝò£ ÙîÇÝÿò ý░©ýé¼ýØ┤Ùïñ. ýòîýá£Ùª¼ ýèñÝéÑÙïñ ýé¼Û│áÙèö LNGÝöîÙ×£Ýè©ýØÿ ýäñÙ╣äýï£ýäñýùÉýä£ LNGÛ░Ç Ùêäý£ÙÉÿýû┤ ÝÅ¡Ù░£Ùí£ ýØ┤ýû┤ýá© 27Ù¬àýØÿ ýé¼ÙºØý×ÉýÖÇ 80Ù¬àýØÿ ÙÂÇýâüý×ÉÛ░Ç Ù░£ýâØÝòÿÛ│á ýò¢ 8ýûÁ Ùï¼Ùƒ¼ýØÿ Û▓¢ýá£ýáü ýåÉýïñýØ┤ Ù░£ýâØÝò£ ÙîÇÝÿò ÝÅ¡Ù░£ ýé¼Û│áýØ┤Ùïñ. Ù▓¿Û©░ýùÉýØÿ Û©░ýèñÙáØÝÿáýùÉýä£ Ù░£ýâØÝò£ ýé¼Û│áÙèö ý▓£ýù░Û░Çýèñ ýÜ┤ýåíÛ┤ÇýØÿ ÝîîýåÉý£╝Ùí£ ýØ©Ýò┤ Ùêäý£ Ù░Å ÝÅ¡Ù░£ýØ┤ Ù░£ýâØÝòÿýÿÇý£╝Ù®░, 24Ù¬àýØÿ ýé¼ÙºØý×ÉýÖÇ 132Ù¬àýØÿ ÙÂÇýâüý×ÉÛ░Ç Ù░£ýâØÝò£ ýï¼Û░üÝò£ ÝÅ¡Ù░£ ýé¼Û│áýØ┤Ùïñ. ÙÿÉÝò£ ýÁ£ÛÀ╝ 2014ÙàäýùÉ Ù»©ÛÁ¡ ýÿñÙª¼Û▒┤ýùÉýä£ Ù░£ýâØÝò£ Û░ÇýèñÝâ▒Ýü¼ ÝÅ¡Ù░£ýé¼Û│áÙèö 2 ýï£Û░ä ÙºîýùÉ ýºäÝÖöÙÉÿýùêýºÇÙºî 5Ù¬àýØÿ ÙÂÇýâüý×ÉÛ░Ç Ù░£ýâØÝòÿÛ│á 400Ù¬àýØ┤ ÙîÇÝö╝Ýò£ ýé¼Û│áýØ┤Ùïñ(Fig. 1). ýØ┤Ùƒ¼Ýò£ ýé¼Û│á ýé¼ÙíÇÙÑ╝ ÝåÁÝò┤ Ù│┤ýòÿýØä Ùòî, LNG Û░ÇýèñýØÿ Ùêäý£Ùí£ ýØ©Ýò£ ÝÅ¡Ù░£ýé¼Û│áÛ░Ç Ù░£ýâØÝòÿÙ®┤ ÙÅîýØ┤Ýé¼ ýêÿ ýùåÙèö ýé¼ÝÜîý×¼Ùé£ ýé¼Û│áÙí£ ýù░Û▓░ÙÉá Û░ÇÙèÑýä▒ýØ┤ Ýü¼Ù»ÇÙí£ LNGýØÿ Ùêäý£Û│╝ ÝÅ¡Ù░£ýØ┤ ýáêÙîÇýáüý£╝Ùí£ Ù░£ýâØÝòÿýºÇ ýòèÙÅäÙíØ Û┤ÇÙá¿ ýï£ýäñÙ¼╝ ýòêýáäýùÉ Ýü░ ýïáÛ▓¢ýØä Û©░ýÜ©ýù¼ýò╝ Ýò£Ùïñ.

ÙîÇÝæ£ýáüýØ© LNG Û┤ÇÙá¿ ýï£ýäñÙ¼╝ýØ© LNG ýáÇý×ÑÝâ▒Ýü¼Ùèö Ùé┤ÔïàýÖ©ýí░ ýØ┤ýñæ ÛÁ¼ýí░Ùí£ ýØ┤Ùú¿ýû┤ýá© ý×êÙïñ. Ùé┤ýí░ýùÉÙèö 9% Ùïêý╝ê Ýò®Û©êýØ┤, ýÖ©ýí░ýùÉÙèö ý¢ÿÝü¼Ùª¼Ýè©Û░Ç Û▒┤ýäñý×¼ÙúîÙí£ ýé¼ýÜ®ÙÉÿÙ®░, Ùé┤ýí░ýÖÇ ýÖ©ýí░ ýé¼ýØ┤ýùÉÙèö Ùï¿ýù┤ý×¼ Ùô▒ý£╝Ùí£ ý▒äýøîýºäÙïñ. Ýè╣Ý×ê LNG ýáÇý×ÑÝâ▒Ýü¼ýØÿ ýÖ©ýí░Ùèö Ùé┤ýí░ýùÉýä£ LNG ý£áý£ýØ┤ Ù░£ýâØÝòÿýÿÇýØä Ùòî ýÖ©ÙÂÇÙí£ýØÿ ý£áý£ýØä ÙºëÙèö ýù¡ÝòáýØä ÝòÿÙ®░, ýÖ©ÙÂÇ ý®Û▓®ýùÉ Ùé┤ýí░ÙÑ╝ Ù│┤Ýÿ©ÝòÿÙèö ýù¡ÝòáýØä Ýò£Ùïñ. Ùö░ÙØ╝ýä£ LNG ýáÇý×ÑÝâ▒Ýü¼ýØÿ ýòêýáäýä▒ýØä ÙåÆýØ┤Û©░ ý£äÝò┤ýä£Ùèö Ùé┤ýí░ Ù┐É ýòäÙïêÙØ╝ ýÖ©ýí░ýØÿ ÛÁ¼ýí░ýáü ýòêýáòýä▒ýØä ÙåÆýØ┤Ùèö Û▓âýØ┤ ýñæýÜöÝòÿÙ®░, ýØ┤ÙÑ╝ ý£äÝò┤ýä£Ùèö ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ýØ©ý×Ñ ýä▒ÙèÑ, Ýê¼ýèÁýä▒, ÛÀáýù┤ ýáÇÝò¡ýä▒ÙèÑ Ùô▒ýØä Ýü¼Û▓î ÝûÑýâü ýï£ý╝£ýò╝ Ýò£Ùïñ.

ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©(Ultra-High-Performance Concrete, UHPC)Ùèö Richard and Cheyrezy (1995)Û░Ç ý▓ÿýØîý£╝Ùí£ Û░£Ù░£Ýò£ Reactive powder concreteÙÑ╝ Ýò£ÛÁ¡ýØä ÝżÝò¿Ýò£ ýù¼Ùƒ¼ ÙéÿÙØ╝ýùÉýä£ Ù░£ýáäýï£ÝéñÙ®░ Û░£Ù░£ÙÉ£ ý×¼ÙúîýØ┤Ùïñ. ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýØ╝Ù░ÿýáüýØ© ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ÙºñýÜ░ ÙåÆýØÇ ýòòýÂòÔïàýØ©ý×Ñ Û░òÙÅäÙÑ╝ ÙéÿÝâÇÙé┤Û│á, Ùé«ýØÇ Û│ÁÛÀ╣ÙÑá Ù░Å Ýê¼ýèÁýä▒ Ùô▒ýØÿ Ùø░ýû┤Ùé£ Ùé┤ÛÁ¼ýä▒ýØä Ù│┤ýØ©Ùïñ. ýØ┤Ùƒ¼Ýò£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Ùø░ýû┤Ùé£ ýä▒ÙèÑýØÇ Ùé«ýØÇ Ù¼╝-Û▓░Ýò®ý×¼ Ù╣äý£¿, Û░òýä¼ý£áýØÿ Ýÿ╝ý×à, ÙºÄýØÇ ýûæýØÿ Ù»©ýä©Ýò£ Ýÿ╝Ýò®Ù¼╝ýØÿ ÝżÝò¿ Ùô▒ýØä ÝåÁÝò┤ ÝÖòÙ│┤ÙÉ£ Û▓âýØ┤Ùïñ. ÛÀ©Ùƒ¼Ùéÿ ýØ┤Ùƒ¼Ýò£ Ùø░ýû┤Ùé£ ýä▒ÙèÑýØä Ù│┤ýØ┤Ùèö ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ÙÑ╝ LNG ýáÇý×ÑÝâ▒Ýü¼ýùÉ ýáüýÜ®ÝòÿÛ©░ ý£äÝò£ ýù░ÛÁ¼Ùèö ÙºñýÜ░ Ù»©ÝØíÝò£ ýïñýáòýØ┤Ùïñ(Kim et al., 2018).

ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý×ÉÛ©░ý╣ÿý£á Ýè╣ýä▒ýØÇ ÛÁ¼ýí░Ù¼╝ýØÿ Ùé┤ÛÁ¼ýä▒Û│╝ ýé¼ýÜ®ýä▒ýØä ÝûÑýâüýï£Ýé¼ ýêÿ ý×êÙèö Ùø░ýû┤Ùé£ Ù│┤ýêÿÔïàÙ│┤Û░ò Ù░®Ù▓ò ýñæýØÿ ÝòÿÙéÿÙí£ ýØ┤Ùèö Ù¼╝Û│╝ Û│ÁÛ©░Ùºî ýí┤ý×¼ÝòÿÙ®┤ Ù░£ýâØ Û░ÇÙèÑÝòÿÙïñ(Neville, 2002). Talaiekhozan et al. (2014)ýùÉ Ùö░ÙÑ┤Ù®┤ ý¢ÿÝü¼Ùª¼Ýè©ýùÉýä£ ý×Éýù░ýáüý£╝Ùí£ Ù░£ýâØÝòá ýêÿ ý×êÙèö ý×ÉÛ©░ý╣ÿý£á Ù░®Ù▓òýØÇ Ùäñ Û░ÇýºÇÙí£ ÙÂäÙÑÿÙÉÿÙ®░, ýØ┤ýñæ Û░Çý×Ñ ÝÜ¿Û│╝ýáüýØ© Ù░®Ù▓òýØÇ Ýâäýé░ý╣╝ýèÿÛ│╝ ýêÿýé░ÝÖöý╣╝ýèÿýØÿ Ýÿòýä▒ýØ┤Ùïñ. ÙÿÉÝò£ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ÙÅÖÛ▓░-ý£ÁÝò┤ Û│╝ýáòýùÉýä£ ý×ÉÛ©░ý╣ÿý£á Ýè╣ýä▒ýØÇ Ùé┤ÛÁ¼ýä▒ýØä ÝûÑýâüýï£Ýé¼ ýêÿ ý×êÙèö ýÜöýåîÙí£ Ù│┤Û│áÙÉÿýùêý£╝Ù®░(McHenry and Brewer, 1945), Ýò┤ýÖ©ýùÉýä£Ùèö ÙÅÖÛ▓░-ý£ÁÝò┤ ýØ┤Ýøä ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý×ÉÛ©░ý╣ÿý£á Ýè╣ýä▒ýùÉ ÙîÇÝò£ ýù░ÛÁ¼Û░Ç ýäáÝûëÙÉ£ Ù░öÛ░Ç ý×êÙïñ(Jacobsen and Sellevold, 1996; Zhu et al., 2012; Jamshidi et al., 2016). ÛÀ©Ùƒ¼Ùéÿ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ÙÅÖÛ▓░-ý£ÁÝò┤ ýØ┤Ýøä ý×ÉÛ©░ý╣ÿý£á Ýè╣ýä▒ýùÉ ÙîÇÝò£ ýù░ÛÁ¼Ùèö ýáäÙ¼┤Ýò£ ýïñýáòýØ┤Ùïñ.

Ùö░ÙØ╝ýä£ Ù│© ýù░ÛÁ¼ýùÉýä£Ùèö LNG Ýâ▒Ýü¼ýØÿ ýÖ©ýí░ ÛÁ¼ýí░Ù¼╝ ýùÉ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ÙÑ╝ ýáüýÜ®Ýòÿýù¼ ýòêýáäýä▒ýØä ÝûÑýâüýï£ÝéñÛ©░ ý£äÝò┤, ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© Ý£¿ Û▒░ÙÅÖÛ│╝ ÛÀáýù┤ Û▒░ÙÅÖ, ý×ÉÛ©░ý╣ÿý£á Û▒░ÙÅÖýùÉ ÙîÇÝò£ ýù░ÛÁ¼ÙÑ╝ ýºäÝûëÝòÿýÿÇÙïñ.

ýï£ÝÄ© ýá£ý×æýùÉ ýé¼ýÜ®ÙÉ£ ý¢ÿÝü¼Ùª¼Ýè© Ù░░Ýò®ýØÇ ÙæÉ ýóàÙÑÿÙí£ Ýò£ÛÁ¡Û░ÇýèñÛ│Áýé¼ýØÿ LNG Ýâ▒Ýü¼ ýÖ©ýí░ Û▒┤ýäñýùÉ ýé¼ýÜ®ÙÉÿÙèö ý¢ÿÝü¼Ùª¼Ýè© Ù░░Ýò®(Normal Concrete, NC)Û│╝ ÙÂüÙ»©ýùÉýä£ ýâüýÜ®ÙÉÿÙèö ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè© Ù░░Ýò®(Ulta-High-Performance Concrete, UHPC)ýØ┤ ýé¼ýÜ®ÙÉÿýùêý£╝Ù®░, Ù░░Ýò®ýùÉ ÙîÇÝò£ ýâüýä©Ýò£ ýáòÙ│┤Ùèö Table 1ýùÉ ÙéÿÝâÇÙé┤ýùêÙïñ. UHPC Ù░░Ýò®ýùÉÙèö Û©©ýØ┤ýÖÇ ýºüÛ▓¢ýØ┤ ÙïñÙÑ© ýä© ýóàÙÑÿýØÿ ýØ╝ý×ÉÝÿò Û░òýä¼ý£áÙÑ╝ ÙÂÇÝö╝ ÙîÇÙ╣ä 2% Ýÿ╝ý×àÝòÿýÿÇý£╝Ù®░, Û░òýä¼ý£áýùÉ ÙîÇÝò£ ýáòÙ│┤Ùèö Table 2ýùÉ ý×Éýä©Ý×ê ÙéÿÝâÇÙé┤ýùêÙïñ.

Table 1ýùÉ ÙéÿÝâÇÙé£ Ù░öýÖÇ Û░ÖýØ┤ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè© Ù░░Ýò®ýØÿ Ù¼╝-Û▓░Ýò®ý×¼(W/B) Ù╣äÙèö 0.40ýØ┤, ý×öÛ│¿ý×¼ý£¿(S/a)ýØÇ 0.44Û░Ç ýáüýÜ®ÙÉÿýùêÙïñ. ýï£Ù®ÿÝè© Û│ä ý×¼ÙúîÙí£ýì¿ ýᣠ1ýóà Ù│┤ÝåÁ ÝżÝïÇÙ×£Ùô£ ýï£Ù®ÿÝè©ýÖÇ ÝöîÙØ╝ýØ┤ýòáýë¼ÙÑ╝ ýé¼ýÜ®ÝòÿýÿÇÛ│á, ÝÖöÝòÖ ÛÁ¼ýä▒ Ù░Å Ù¼╝Ùª¼ýáü Ýè╣ýä▒ýØÇ Table 3ýùÉ ÙéÿÝâÇÙé┤ýùêÙïñ. ý×öÛ│¿ý×¼Ùí£Ùèö Ù¬¿Ù×ÿÛ░Ç, ÛÁÁýØÇ Û│¿ý×¼Ùí£Ùèö ý×ÉÛ░êýØä ýé¼ýÜ®ÝòÿýÿÇý£╝Ù®░, Û│ÁÛ©░ýù░Ýûëýá£(AE)ýÖÇ Û░Éýêÿýá£(SP)ÙÑ╝ ýé¼ýÜ®Ýòÿýù¼ ýáüýáêÝò£ ý×æýùàýä▒ýØä ÝÖòÙ│┤ÝòÿýÿÇÙïñ.

Control Ù░░Ýò®Û│╝ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî UHPCýØÿ Ù░░Ýò®ýØÇ ýâüÙîÇýáüý£╝Ùí£ ÙºñýÜ░ Ùé«ýØÇ 0.20ýØÿ Ù¼╝-Û▓░Ýò®ý×¼ Ù╣äÙÑ╝ ýáüýÜ®ÝòÿýÿÇÙïñ. Û▓░Ýò®ý×¼Ùí£ýì¿ ýᣠ1ýóà Ù│┤ÝåÁ ÝżÝïÇÙ×£Ùô£ ýï£Ù®ÿÝè©ýÖÇ ýºÇÙÑ┤ý¢öÙèä ýïñÙª¼ý╣┤Ýô©(Zirconium silica fume, Zr SF)ýØä ýé¼ýÜ®ÝòÿýÿÇý£╝Ù®░, ýâüýä©Ýò£ ÝÖöÝòÖ ÛÁ¼ýä▒ Ù░Å Ù¼╝Ùª¼ýáü Ýè╣ýä▒ýØÇ Table 3ýùÉ ÙéÿÝâÇÙé┤ýùêÙïñ. ý®ýáä ýØ┤Ùíá Ù░Å ýé¼ýáä ý£áÙÅÖÝòÖýáü ýïñÝùÿýØä Ù░öÝâòý£╝Ùí£ ÝÅëÛÀá ý×àÛ▓¢ Ýü¼Û©░ 0.25 mmýØÿ Ýÿ©ýú╝ýé░ ÛÀ£ýé¼ÙÑ╝ ý×öÛ│¿ý×¼Ùí£ ýé¼ýÜ®ÝòÿýÿÇÛ│á, ý®ýáäý×¼Ùí£ýì¿ ÝÅëÛÀá ý×àÛ▓¢ Ýü¼Û©░ 4.2 ÒÄøýØÿ ýïñÙª¼ý╣┤ ÙÂäÙºÉýØä ýé¼ýÜ®ÝòÿýÿÇÙïñ(Chan et al., 2000). ÛÁÁýØÇ Û│¿ý×¼Ùèö UHPCýØÿ ÛÀáýºêýä▒ýØä Ýò┤ý╣ÿÛ│á Ý£¿ Ù░Å ýØ©ý×Ñ Û░òÙÅäýùÉ Ýü░ ýÿüÝûÑýØä Ù»©ý╣ÿÙèö ýä¼ý£á ÙÂÇý░®Û░òÙÅäÙÑ╝ Û░Éýåîýï£ÝéñÛ©░ ÙòîÙ¼©ýùÉ Ù░░Ýò®ýùÉýä£ ýá£ýÖ©ÝòÿýÿÇÙïñ(Orgass and Klug, 2004; Aydin et al., 2010). ÙÿÉÝò£ ýáüýáêÝò£ ý£áÙÅÖýä▒ Ù░Å ý×ÉÛ©░ý®ýáäýä▒ýØä ÝÖòÙ│┤ÝòÿÛ©░ ý£äÝòÿýù¼ ÝÅ┤Ùª¼ý╣┤ÙÑ┤Ù│Áýï£Û│ä Û│áýä▒ÙèÑ Û░Éýêÿýá£(SP)ÙÑ╝ ýé¼ýÜ®ÝòÿýÿÇý£╝Ù®░, Û░Éýêÿýá£Û░Ç ÝżÝò¿ÝòÿÛ│á ý×êÙèö 70%ýØÿ ýêÿÙÂäýØä Û│áÙáñÝòÿýù¼ Ù░░Ýò®ýùÉ ýáüýÜ®ÝòÿýÿÇÙïñ.

ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî UHPC Ù░░Ýò®ýØÿ ÙºñýÜ░ ÙåÆýØÇ ÙÂäý▓┤ÙƒëÛ│╝ ÙºñýÜ░ Ùé«ýØÇ Ù¼╝-Û▓░Ýò®ý×¼ Ù╣ä, Û░òýä¼ý£áýØÿ Ýÿ╝ý×à Ùô▒ýØÿ Ýè╣ýä▒ýØä Û│áÙáñÝòÿýù¼ Ýè╣Ù│äÝò£ Ýÿ╝Ýò® Ù░Å ÝâÇýäñ Ù░®ýïØýØä ýáüýÜ®ÝòÿýÿÇÙïñ. ýé¼ýÜ®ÙÉÿÙèö Ù¬¿Ùôá Û▒┤ý×¼ÙúîýØ© ýï£Ù®ÿÝè© ýÖÇ ýºÇÙÑ┤ý¢öÙèä ýïñÙª¼ý╣┤Ýô©, ÛÀ£ýé¼, ýïñÙª¼ý╣┤ ÙÂäÙºÉýØä Hobart type mixerÙÑ╝ ýØ┤ýÜ®Ýòÿýù¼ 10ÙÂä ÙÅÖýòê ýáÇýåìýùÉýä£ Ýÿ╝Ýò®ÝòÿýÿÇý£╝Ù®░, ýØ┤Ýøä Ù¼╝Û│╝ ýä×ýØ© Û░Éýêÿýá£ÙÑ╝ ýÂöÛ░ÇÝò£ ÙÆñ Û│áýåìýùÉýä£ 10ÙÂä ÙÅÖýòê ýÂöÛ░Çýáüý£╝Ùí£ Ýÿ╝Ýò®ÝòÿýÿÇÙïñ. ÙºêýºÇÙºëý£╝Ùí£ Û░òýä¼ý£áÙÑ╝ Ù¡ëý╣ÿýºÇ ýòèÙÅäÙíØ ýí░ýï¼ýèñÙƒ¢Û▓î ýÂöÛ░ÇÝòÿýù¼ 5ÙÂä ÙÅÖýòê Ýÿ╝Ýò® ÝòÿýÿÇÙïñ.

Yoo et al. (2014)ýùÉ Ùö░ÙÑ┤Ù®┤ UHPCýØÿ Ý£¿ ýä▒ÙèÑÛ│╝ Ù░ÇýáæÝò£ Û┤ÇÛ│äÙÑ╝ Û░ûÙèö Ùï¿ý£äÙ®┤ýáü Ùï╣ Û░òýä¼ý£á Û░£ýêÿÙèö ÝâÇýäñ Ù░®ýïØýùÉ Ýü¼Û▓î ýÿüÝûÑýØä Ù░øÛ©░ ÙòîÙ¼©ýùÉ, Ù¬¿Ùôá ýï£ÝÄ©ýØÇ Ýò£ ý¬¢ Ù¬¿ýä£Ùª¼ýùÉýä£ Ù░ÿÙîÇÝÄ© Ù¬¿ýä£Ùª¼ Ù░®ÝûÑý£╝Ùí£ Ù░░Ýò®ýØä ÝØÿÙáñýú╝Ù®░ ÝâÇýäñÝòÿýù¼ ýä¼ý£á Ù░░ýù┤ýØ┤ ýØ©ý×ÑÙáÑýØ┤ ý×æýÜ®ÝòÿÙèö Ù░®ÝûÑÛ│╝ ÝÅëÝûëÝò£ Ù░®ÝûÑýØä Û░ûÙÅäÙíØ ÝòÿýÿÇÙïñ. ýâüÛ©░ýØÿ ý×æýùàýØ┤ ýÖäÙúîÝò£ ýºüÝøä ÝâÇýäñÙÉ£ Ýæ£Ù®┤ýØä ÝöîÙØ╝ýèñÝï▒ Ù╣äÙïÉÙí£ Ùì«ýû┤ Û©ëÛ▓®Ýò£ ýêÿÙÂä ýªØÙ░£ýØä Ù░®ýºÇÝòÿýÿÇÙïñ. ÝâÇýäñýØ┤ ýÖäÙúîÙÉ£ ýï£ÝÄ©ýØÇ ýâüýÿ¿ýùÉýä£ 24ýï£Û░äýØÿ ýûæýâØ ýØ┤Ýøä ÝâêÝÿòÝò£ ÙÆñ 90 ┬░C ýÿ¿ÙÅäýùÉýä£ 72ýï£Û░ä ÙÅÖýòê ýªØÛ©░ýûæýâØýØä ýïñýï£ÝòÿýÿÇÙïñ.

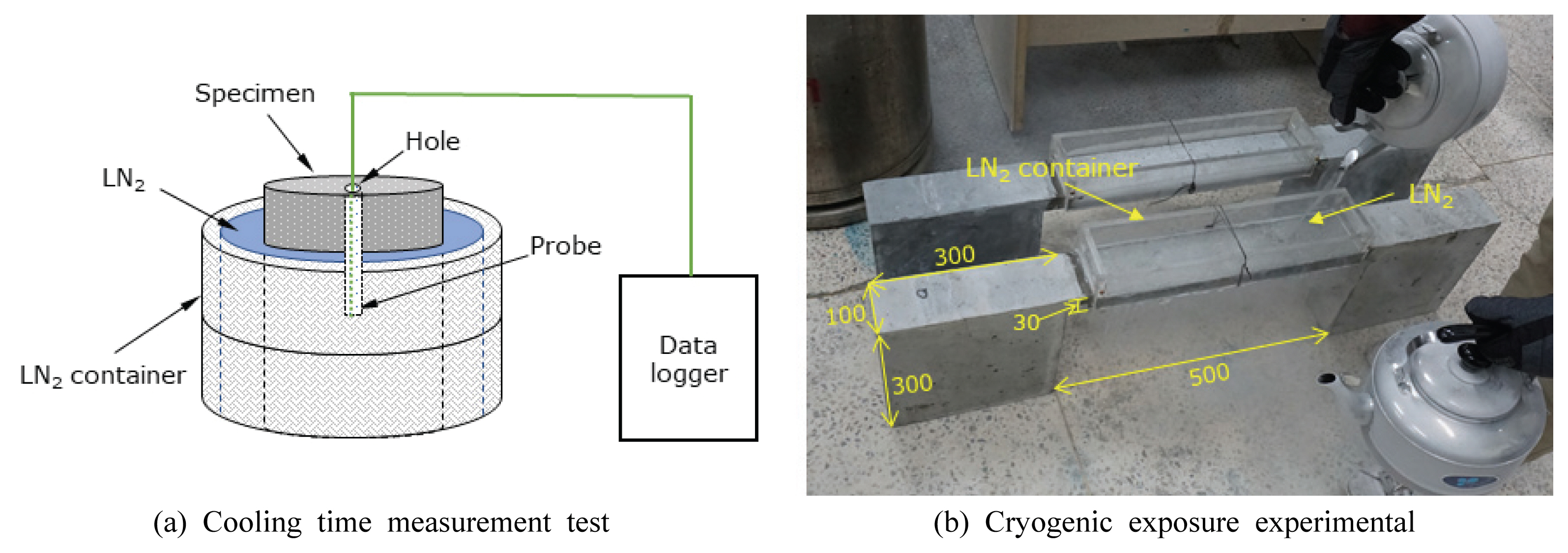

ýïñÝùÿýØä ý£äÝò┤ ýá£ý×æÙÉ£ ýï£ÝÄ©ýØÇ Ýü¼Û▓î ýä© ýóàÙÑÿÙí£, Ý£¿ ýïñÝùÿýØä ý£äÝò£ 30 ├ù 100 ├ù 400 mm3 Ýü¼Û©░ýØÿ ýûçýØÇ Ù│┤ ÝÿòÝâ£ýØÿ ýï£ÝÄ©Û│╝ Fig. 2(a)ýÖÇ Û░ÖýØÇ ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿýØä ý£äÝò£ ├© 100 ├ù 200 mm Ýü¼Û©░ýØÿ ýøÉýú╝Ýÿò ýï£ÝÄ© ýñæýòÖýùÉ 100 mm Û╣èýØ┤ýØÿ ý×æýØÇ ÛÁ¼Ù®ìýØ┤ Ùܽ٪░ ýï£ÝÄ©ýØä ýá£ý×æÝòÿýÿÇÛ│á ý┤êýáÇýÿ¿ ÙâëÛ░ü ýïñÝùÿýØä ý£äÝò┤ Fig. 2(b)ýÖÇ Û░ÖýØ┤ 30 ├ù 100 ├ù 500 mm3 Ýü¼Û©░ýØÿ ýûçýØÇ Ù│┤Û░Ç ýûæý¬¢ ÙüØýØÿ 100 ├ù 300 ├ù 300 mm3 Ýü¼Û©░ýØÿ ý¢ÿÝü¼Ùª¼Ýè© Ùì®ýû┤Ùª¼ýùÉ ýù░Û▓░ÙÉÿýû┤ý×êÙèö ÝÿòÝâ£ýØÿ ýï£ÝÄ©ýØä ýá£ý×æÝòÿýÿÇÙïñ. ý┤êýáÇýÿ¿ ÙâëÛ░ü ýïñÝùÿ ýØ┤Ýøä Fig. 2(b)ýØÿ Ýò┤Ùï╣ ýï£ÝÄ©ýØÇ ýñæýòÖÙÂÇÙÑ╝ 400 mm Û©©ýØ┤Ùí£ ýáêÙï¿Ýòÿýù¼ 30 ├ù 100 ├ù 400 mm3 Ýü¼Û©░Ùí£ ÙºîÙôá ÙÆñ Ý£¿ ýïñÝùÿýùÉ ý×¼ýé¼ýÜ®ÙÉÿýùêÙïñ.

LNG ýáÇý×Ñ Ýâ▒Ýü¼ýØÿ ý┤êýáÇýÿ¿ ý£áý▓┤Û░Ç ý¢ÿÝü¼Ùª¼Ýè©ýùÉ ýáæý┤ëÝòÿýÿÇýØä ÙòîýØÿ ýÿüÝûÑýØä ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò┤ ÙüôÙèöýáÉýØ┤ ýò¢ ÔÇô196 ┬░CýØ© ýòíý▓┤ýºêýåî(Liquid Nitrogen, LN2)ÙÑ╝ ýØ┤ýÜ®Ýòÿýù¼ ýºüýáæýáüýØ© ý┤êýáÇýÿ¿ ÙâëÛ░üýïñÝùÿýØä ýïñýï£ÝòÿýÿÇÙïñ. LNGýØÿ ÙüôÙèöýáÉýØ┤ ýò¢ ÔÇô162 ┬░C ý×äýØä Û│áÙáñÝòÿýù¼ ýï£ÝÄ©ýØÿ ÙâëÛ░ü Ù¬®Ýæ£ ýÿ¿ÙÅäÙèö ÔÇô165 ┬░CÙí£ ýäñýáòÝòÿýÿÇÙïñ. ÙâëÛ░üýïñÝùÿ ýñæ ýï£ÝÄ© Ùé┤ÙÂÇýØÿ ýÿ¿ÙÅä Ù│ÇÝÖöÙÑ╝ ýºüýáæ ý©íýáòÝòÿÙèö Û▓âýØÇ ÙºñýÜ░ ýû┤ÙáñýÜ┤ Ù░®Ù▓òýØ┤Ù»ÇÙí£, ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿýØä ýïñýï£Ýòÿýù¼ ÙïñÙÑ© ÝÿòÝâ£ýØÿ ý¢ÿÝü¼Ùª¼Ýè© ýï£ÝÄ©ýØÿ Ùé┤ÙÂÇÛ░Ç ý┤êýáÇýÿ¿(ÔÇô165 ┬░C)Û╣îýºÇ ÙâëÛ░üÙÉÿÙèöÙì░ ÝòäýÜöÝò£ ýï£Û░äýØä ýÂöýáòÝòÿýÿÇÙïñ.

Fig. 2(a)Ùèö ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿýØä ÙéÿÝâÇÙé©Ùïñ. ýøÉýú╝Ýÿò ýï£ÝÄ© ýñæýòÖÙÂÇýØÿ ý×æýØÇ ÛÁ¼Ù®ìýùÉ ýÿ¿ÙÅäÛ│äÙÑ╝ ýé¢ý×àÝòÿýù¼ ýÖ©ÙÂÇ Ýæ£Ù®┤ýØ┤ ý┤êýáÇýÿ¿ýùÉ Ùà©ý£ÙÉÿýùêýØä Ùòî Ùé┤ÙÂÇ ýñæýï¼ÙÂÇýØÿ ýÿ¿ÙÅä Ù│ÇÝÖöÙÑ╝ ý©íýáòÝòÿýÿÇý£╝Ù®░, ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè© ýï£ÝÄ©Û│╝ S65 Û░òýä¼ý£áÛ░Ç ýé¼ýÜ®ÙÉ£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè© ýï£ÝÄ©ýØä ÙîÇýâüý£╝Ùí£ ýïñÝùÿýØä ýïñýï£ÝòÿýÿÇÙïñ.

Fig. 2(b)Ùèö LNG Ýâ▒Ýü¼ýØÿ ýÖ©ýí░Ùí£ ýé¼ýÜ®ÙÉÿÙèö ý¢ÿÝü¼Ùª¼Ýè©ýùÉ LNGÛ░Ç ý£áý£ÙÉÿýùêýØä Ùòî ÛÀáýù┤ Û▒░ÙÅÖ Ù░Å ýåÉýâüýØä Ù¬¿ýé¼ÝòÿÛ©░ ý£äÝò£ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýØä ÙéÿÝâÇÙé©Ùïñ. ýòíý▓┤ýºêýåîÙÑ╝ ýñæýòÖÙÂÇýùÉ ýºüýáæýáüý£╝Ùí£ Ùà©ý£ÝòÿýÿÇý£╝Ù®░, ýûæ ÙüØÙï¿ýØÿ ý╗ñÙïñÙ×Ç ý¢ÿÝü¼Ùª¼Ýè© ÙºñýèñÙÑ╝ ýØ┤ýÜ®Ýò┤ ý┤êýáÇýÿ¿ý£╝Ùí£ ýØ©Ýò£ ýñæýòÖÙÂÇýØÿ ýêÿýÂòýØ┤ ÛÁ¼ýåìÙÉÿÛ▓î ÝòÿýÿÇÙïñ. ýñæýòÖÙÂÇýùÉ ýòíý▓┤ýºêýåîÙÑ╝ Ùï┤ýòäÙæÉÛ©░ ý£äÝò┤ ýòäÝü¼Ùª┤ýØä Ù│╝Ýè©ýÖÇ ÙäêÝè©ÙÑ╝ ýØ┤ýÜ®Ýòÿýù¼ ýí░Ùª¢ Ù░Å ÙÂÇý░®ÝòÿýÿÇÙïñ. ýòíý▓┤ýºêýåîÛ░Ç ýâêýû┤ÙéÿÛ░ÇýºÇ ýòèÙÅäÙíØ ýïñÝùÿ ÙÅäýñæ ýâêýû┤ÙéÿÛ░ÇýºÇ ýòèÙÅäÙíØ ýòäÝü¼Ùª┤ÝîÉÛ│╝ ýï£ÝÄ©ýØÿ ÝïêýâêÙèö ýïñÙª¼ý¢ÿýØä ýØ┤ýÜ®Ýò┤ Ù░ÇÝÅÉÝòÿýÿÇÙïñ. ýâüÙï¿ Ýæ£Ù®┤ýùÉýä£ ýòíý▓┤ýºêýåî Ùà©ý£ýØä ýï£ý×æÝòÿýù¼ ÝòÿÙï¿ýØÿ Ýæ£Ù®┤ýØ┤ ý┤êýáÇýÿ¿ýùÉ ÙÅäÙï¼Ýòá Ùòî Û╣îýºÇ ýò¢ 20ÙÂä ÙÅÖýòê ýïñÝùÿýØä ýºäÝûëÝòÿýÿÇý£╝Ù®░, ýïñÝùÿ ýóàÙúî ýªëýï£ Û┤æÝòÖÝÿäÙ»©Û▓¢ýØä ýØ┤ýÜ®Ýòÿýù¼ Ýæ£Ù®┤Û┤Çý░░ýØä ýïñýï£ÝòÿýÿÇÙïñ.

ÙÿÉÝò£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û▓¢ýÜ░ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ÙºñýÜ░ ÙåÆýØÇ ÙºñÝè©Ùª¡ýèñ Û░òÙÅäÙÑ╝ Ù│┤ýØ┤Û│á, Ùé«ýØÇ Ù¼╝-Û▓░Ýò®ý×¼ Ù╣äÙí£ ýØ©Ýò┤ ýáüýØÇ ýûæýØÿ Û│ÁÛÀ╣ýêÿÙÑ╝ ÝżÝò¿ÝòÿÛ│á ý×êÙïñ. ÙÿÉÝò£ ý▓┤ýáüÙ╣ä 2%ýØÿ ýØ╝ý×ÉÝÿò Û░òýä¼ý£áÙí£ Ù│┤Û░òÙÉÿýû┤ý×êÛ©░ ÙòîÙ¼©ýùÉ ý▓½ ÛÀáýù┤ ýØ┤Ýøä ÝòÿýñæýØ┤ Û░ÉýåîÝòÿýºÇ ýòèÛ│á ýªØÛ░ÇÝòÿÙèö ÛÀáýù┤ Ýøä ýù░ýä▒(Strain- and deflection hardening) Û▒░ÙÅÖýØä Ù│┤ýØ┤Ù®░ ÙåÆýØÇ ýØ©ý×Ñ ýáÇÝò¡ýä▒ýØä Û░ûÙèö Û▓âýØ┤ Ýè╣ýºòýØ┤Ùïñ. Ùö░ÙØ╝ýä£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©Ù│┤Ùïñ ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýò£ ÛÀáýù┤ ýáÇÝò¡ýä▒ýØ┤ ÙåÆÛ©░ ÙòîÙ¼©ýùÉ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿ ýØ┤Ýøä ý×¼Ùï¿ÙÉ£ ýï£ÝÄ©ýØä ÙîÇýâüý£╝Ùí£ 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýØä ýïñýï£ÝòÿýÿÇÙïñ. Û░òýä¼ý£áÛ░Ç ÝżÝò¿ÙÉ£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýØ©ý×Ñ Ù░Šݣ¿ ÝòÿýñæýØ┤ ý×æýÜ®ÝòÿýÿÇýØä Ùòî ý▓½ ÛÀáýù┤ýØ┤ Ù░£ýâØÝò£ ýØ┤Ýøä ÛÀáýù┤ Ýøä ýù░ýä▒ Û▒░ÙÅÖýØä Ù│┤ýØ┤Ù®░ ýä¼ý£á Û░ÇÛÁÉÝÜ¿Û│╝ÙÑ╝ ÝåÁÝò£ 100 ÒÄø Ù»©ÙºîýØÿ ýêÿÙºÄýØÇ Ù»©ýä©ÛÀáýù┤ýØä ýêÿÙ░ÿÝòÿÛ▓î ÙÉ£Ùïñ. Ùö░ÙØ╝ýä£ ýêÿÙºÄýØÇ Ù»©ýä©ÛÀáýù┤ýØ┤ ýêÿÙ░ÿÙÉ£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ÙÑ╝ ýòíý▓┤ýºêýåîýùÉ ýºüýáæýáüý£╝Ùí£ Ùï┤Û░Çýä£ ýò¢ Ýò£ ýï£Û░äýØÿ ý®ÙÂäÝò£ ýï£Û░ä ÙÅÖýòê 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ýØä ýïñýï£ÝòÿýÿÇÙïñ. ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Ù»©ýä©ÛÀáýù┤ ý£áÙÅäÙèö 4ýáÉ Ý£¿ ýïñÝùÿýØä ÝåÁÝò┤ ÝòÿýñæýØä ý×æýÜ®Ýò¿ý£╝Ùí£ýì¿ ýïñýï£ÙÉÿýùêÛ│á, ýä¼ý£á ýóàÙÑÿýùÉ Ùö░ÙØ╝ ýÁ£ÙîÇ ÝòÿýñæýØ┤ Ùï¼ÙØ╝ýºÇÛ©░ ÙòîÙ¼©ýùÉ ýâüýÿ¿(Ambient)ýùÉýä£ýØÿ ýïñÝùÿ Û▓░Û│╝ÙÑ╝ ÝåáÙîÇÙí£ ý×æýÜ® ÝòÿýñæýØä ÙïñÙÑ┤Û▓î ÝòÿýÿÇÙïñ. ý×æýÜ® ÝòÿýñæýØÇ ý▓½ ÛÀáýù┤ýØ┤ Ù░£ýâØÝûêýØä Ùòî Ýòÿýñæ Û░ÆÛ│╝ ýÁ£ÙîÇ Ýòÿýñæ Û░ÆýØÿ ýñæÛ░ä Û░Æý£╝Ùí£ Û▓░ýáòÝòÿýÿÇý£╝Ù®░ Table 4ýÖÇ Û░ÖÙïñ.

ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© ýù¡ÝòÖýáü Û▒░ÙÅÖýØä ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò┤ 4ýáÉ Ý£¿ ýïñÝùÿýØä ýºäÝûëÝòÿýÿÇÙïñ. ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýâüýÿ¿(Ambient) Ù░Å ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿ ýØ┤Ýøä 3ýØ╝ Û©░Û▒┤ ýûæýâØ(Cryogenic-AC)ýØÿ ÙæÉ ýóàÙÑÿ ýí░Û▒┤ ýòäÙ×ÿýùÉýä£ Ý£¿ ýï£ÝùÿýØä ýïñýï£ÝòÿýÿÇý£╝Ù®░, ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýâüýÿ¿(Ambient) Ù░Å ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä 3ýØ╝ Û©░Û▒┤ ýûæýâØ(Cryogenic-AC), ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä 28ýØ╝ ýêÿýñæýûæýâØ(Cryogenic-WC)ýØÿ ýä© ýóàÙÑÿ ýí░Û▒┤ ýòäÙ×ÿýùÉýä£ Ý£¿ ýï£ÝùÿýØä ýïñýï£ÝòÿýÿÇÙïñ.

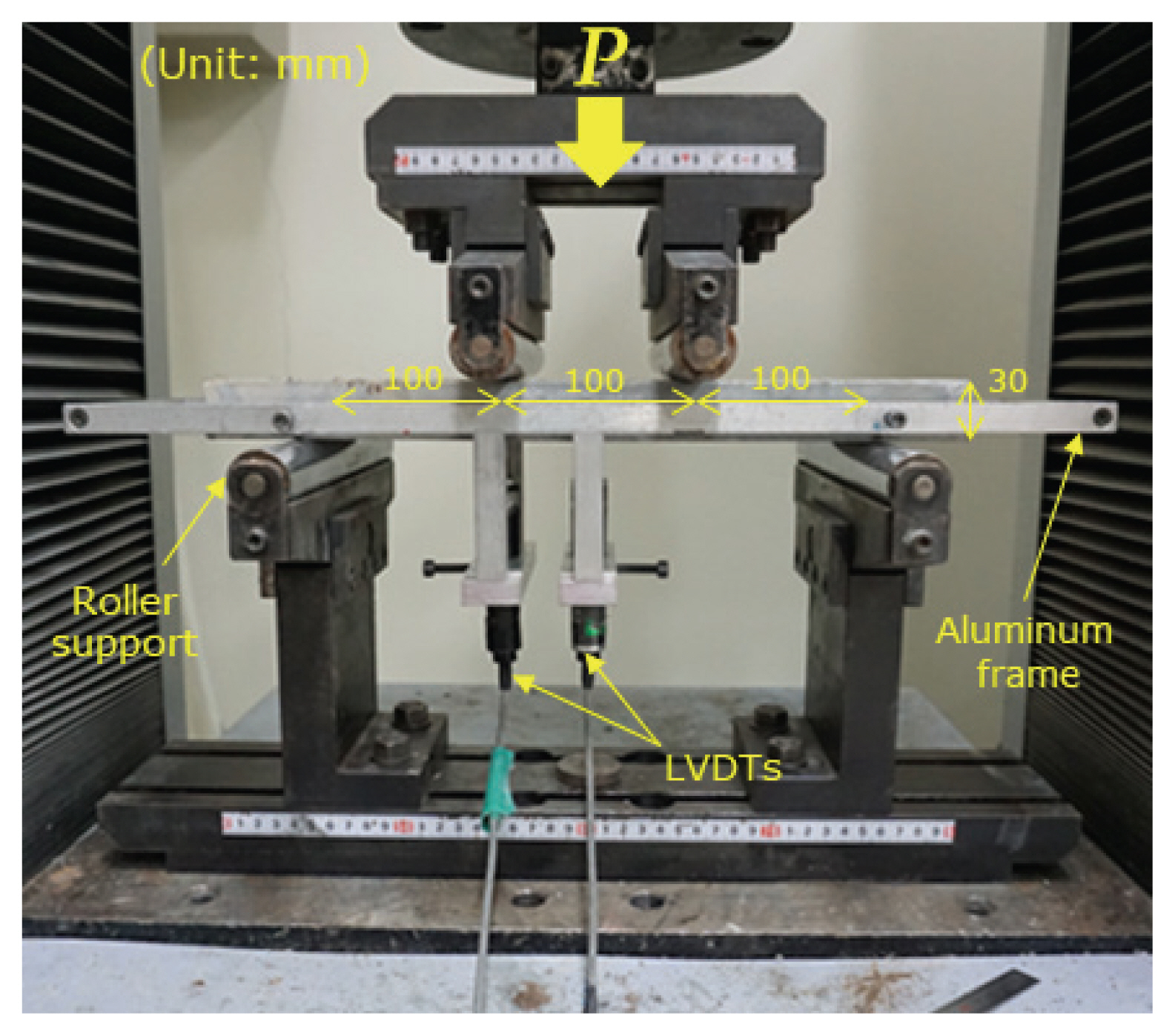

Fig. 3ýØÇ 4ýáÉ Ý£¿ ýïñÝùÿ ýàïýùàýØä ÙéÿÝâÇÙé┤Ù®░, ýï£ÝÄ©ýØÿ Ýü¼Û©░(30 ├ù 100 ├ù 400 mm3)ÙÑ╝ ýá£ýÖ©ÝòÿÛ│á ASTM C1609 (2012)ýùÉ Ùö░ÙØ╝ ýºäÝûëÙÉÿýùêÙïñ. ýïñÝùÿ Û▓░Û│╝ýØÿ ýáòÝÖòýä▒ýØä ÙåÆýØ┤Û©░ ý£äÝò┤ Û░ü Ù│Çýêÿ Ù░Å ýí░Û▒┤Ù│äÙí£ 3Û░£ýØÿ ýï£ÝÄ©ýØä ýá£ý×æÝòÿýù¼ ýï£ÝùÿýØä ýïñýï£ÝòÿýÿÇÙïñ. 250 kN ýܮكëýØÿ ÙºîÙèÑý×¼Ùúîýï£ÝùÿÛ©░(UTM)ýØä ýØ┤ýÜ®Ýòÿýù¼ Ù│Çý£äýá£ýû┤ Ù░®ýïØý£╝Ùí£ 0.04 mm/minýØÿ ýåìÙÅäÙí£ ýØ╝ýÂò ÝòÿýñæýØä ýáüýÜ®ÝòÿýÿÇÙïñ. ýáüýÜ®ÙÉ£ ÝòÿýñæýØÇ Ùí£Ùô£ýàÇýØä ýØ┤ýÜ®Ýòÿýù¼ ý©íýáòÝòÿýÿÇý£╝Ù®░, ýºÇýáÉýØÿ ýí░Û▒┤ýØÇ Roller supportÛ░Ç ýáüýÜ®ÙÉÿýùêÙïñ. ýñæýòÖÙÂÇýØÿ ý▓ÿýºÉýØÇ Linear variable differential transformers (LVDTs)ÙÑ╝ ýØ┤ýÜ®Ýòÿýù¼ ýÁ£ÙîÇ 9 mmÛ╣îýºÇ ý©íýáòÝòÿýÿÇý£╝Ù®░, LVDTsÙèö ýòîÙú¿Ù»©Ùèä ÝöäÙáêý×äýØä ýØ┤ýÜ®Ýòÿýù¼ ýïñÝùÿý▓┤ýùÉ Û│áýáòÝòÿýÿÇÙïñ.

1ý░¿ Ù░Å 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý×ÉÛ©░ý╣ÿý£á ýä▒ÙèÑýØä ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò┤ 28ýØ╝ ÙÅÖýòê ýâüýÿ¿ýØÿ ýêÿýí░ýùÉýä£ ýêÿýñæýûæýâØýØ┤ ýïñýï£ÙÉÿýùêÙïñ.

ý┤êýáÇýÿ¿ ÙâëÛ░ü ýáäÝøä ýï£ÝÄ©ýØÿ ÛÀáýù┤ Û▒░ÙÅÖýØä ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò┤ ýÁ£ÙîÇ 500Ù░░ý£¿ýØÿ Û┤æÝòÖÝÿäÙ»©Û▓¢ýØä ýØ┤ýÜ®Ýòÿýù¼ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Ýæ£Ù®┤ýØä Û┤Çý░░ÝòÿýÿÇÙïñ. ÙÿÉÝò£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ 28ýØ╝ ÙÅÖýòêýØÿ ýêÿýñæ ýûæýâØýùÉ Ùö░ÙÑ© ý×ÉÛ©░ý╣ÿý£á Û▒░ÙÅÖýØä ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò┤ 15 ├ù 15 ├ù 15 mm3 Ýü¼Û©░ýØÿ ýâÿÝöîýØä ýÂöý£Ýòÿýù¼ ýêÿýñæýûæýâØ Û©░Û░ä(0, 1, 7, 14, 28ýØ╝)ýùÉ Ùö░ÙØ╝ ýú╝ýé¼ýáäý×ÉÝÿäÙ»©Û▓¢(Scanning Electron Microscopy, SEM) ý┤¼ýÿüýØä ýºäÝûëÝòÿýÿÇÛ│á, ÛÀáýù┤ ý▒äýøÇ Ù¼╝ýºêýØä ÝÖòýØ©ÝòÿÛ©░ ý£äÝò┤ Energy Dispersive X-ray spectroscopy (EDX) ÙÂäýäØýØä ýºäÝûëÝòÿýÿÇÙïñ.

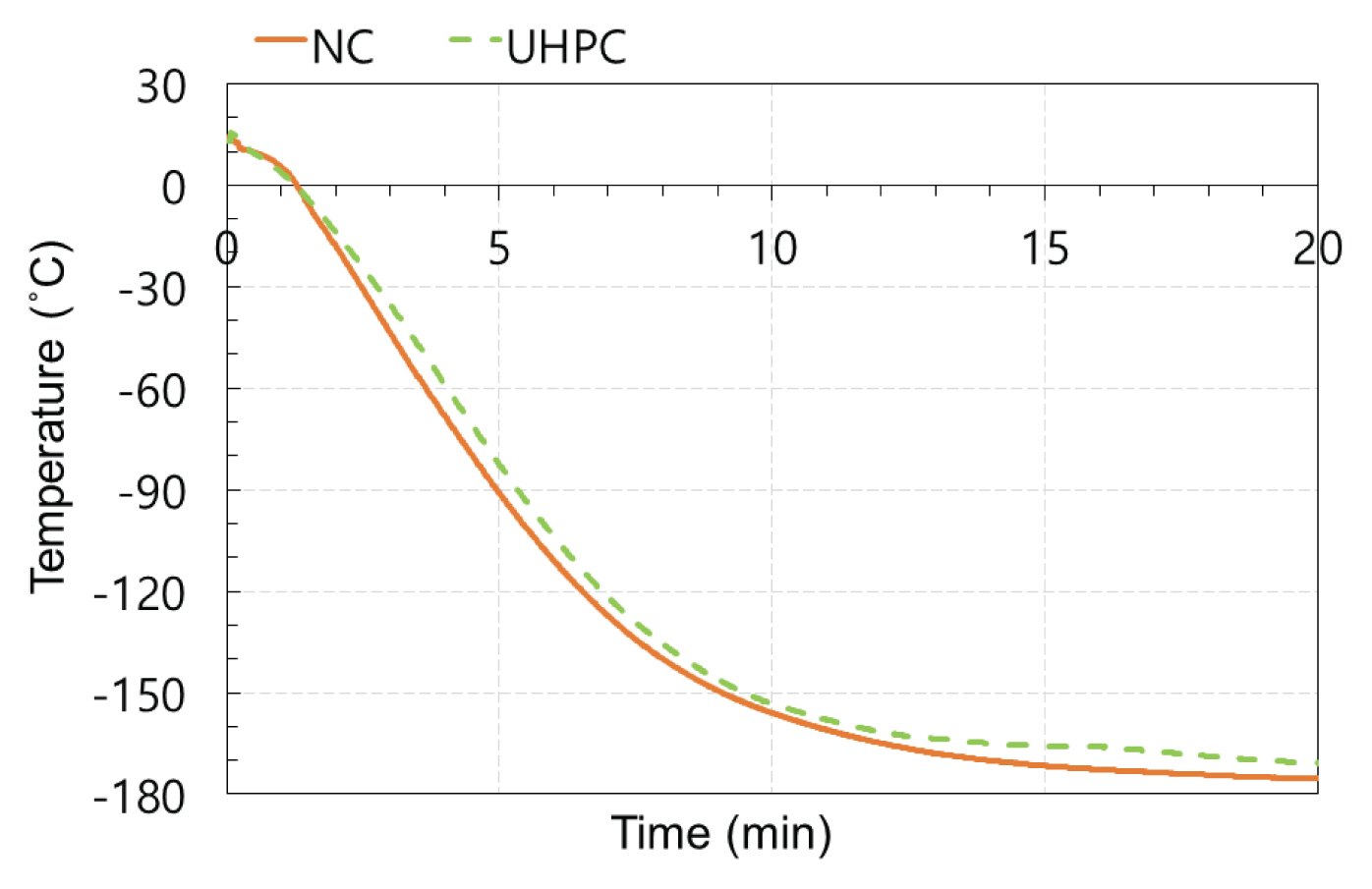

Fig. 4Ùèö ýòíý▓┤ýºêýåî ÙâëÛ░ü ýï£Û░äýùÉ Ùö░ÙÑ© ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè© ýøÉýú╝Ýÿò ýï£ÝÄ©ýØÿ ýñæýï¼ÙÂÇýØÿ ýÿ¿ÙÅä Ù│ÇÝÖöÙÑ╝ ÙéÿÝâÇÙé©Ùïñ. ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ýï£Û░äýùÉ Ùö░ÙÑ© ýñæýï¼ÙÂÇ ýÿ¿ÙÅä Û░Éýåî Û▓¢ÝûÑýØÇ Ýü░ ý░¿ýØ┤ÙÑ╝ Ù│┤ýØ┤ýºÇ ýòèý£╝Ù®░, ýñæýï¼ÙÂÇýØÿ ýÿ¿ÙÅäÙèö ý┤êÛ©░ýùÉ ýò¢ ÔÇô 150 ┬░CÛ╣îýºÇ Û©ëÛ▓®ÝòÿÛ▓î Û░ÉýåîÝòÿÙèö Û▓¢ÝûÑýØä Ù│┤ýØ©Ùïñ. ýØ┤Ýøä ýñæýï¼ÙÂÇýØÿ ýÿ¿ÙÅäÙèö ý▓£ý▓£Ý×ê Û░ÉýåîÝòÿÙèö Û▓¢ÝûÑýØä Ù│┤ýØ┤Ù®░, 20ÙÂäýØ┤ ÙâëÛ░üýï£Û░äýØ┤ ýºÇÙé£ Ýøä ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ýñæýï¼ÙÂÇ ýÿ¿ÙÅäÙèö Û░üÛ░ü ÔÇô 175 ┬░CýÖÇ ÔÇô 171 ┬░CÙí£ Û©░ÙíØÙÉÿýùêÙïñ.

ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Û░Ç Ù¬®Ýæ£ ÙâëÛ░ü ýÿ¿ÙÅä(ÔÇô165 ┬░C)ýùÉ ÙÅäÙï¼ÝòÿÛ©░Û╣îýºÇ Û░üÛ░ü 12ÙÂä, 14ÙÂäýØÿ ýï£Û░äýØ┤ ýåîýÜöÙÉÿýùêÙïñ. ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ ýé¼ýÜ®ÙÉ£ ýï£ÝÄ©ýØÿ ÝÿòÝâ£ýÖÇ ýòíý▓┤ýºêýåîÛ░Ç ýáæý┤ëÝòÿÙèö Ýæ£Ù®┤ýáüýØÇ ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿýùÉ ýé¼ýÜ®ÙÉ£ ýøÉýú╝Ýÿò ýï£ÝÄ©Û│╝ ýâüýØ┤ÝòÿÙ»ÇÙí£, ýïñýᣠý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýùÉýä£ ÙâëÛ░üýï£Û░äýùÉ Ùö░ÙÑ© ýï£ÝÄ© Ùé┤ÙÂÇýØÿ ýÿ¿ÙÅä Ù│ÇÝÖö ýûæýâüýØÇ ÙïñÙÑ┤Û▓î ÙéÿÝâÇÙéá Û▓âýØ┤Ùïñ. Ùö░ÙØ╝ýä£ ýØ┤Ùƒ¼Ýò£ ý░¿ýØ┤ÙÑ╝ Û│áÙáñÝòÿýù¼ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýùÉ ýé¼ýÜ®ÙÉ£ ýï£ÝÄ©ýØ┤ Ù¬®Ýæ£ ýÿ¿ÙÅäýùÉ ÙÅäÙï¼ÝòÿÛ©░Û╣îýºÇýØÿ ýï£Û░äýØä ýÂöýáòÝòÿýù¼ýò╝ Ýò£Ùïñ. ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿýùÉ ýé¼ýÜ®ÙÉ£ ýøÉýú╝Ýÿò ýï£ÝÄ©ýØÇ Fig. 2(a)ýùÉ ÙéÿÝâÇÙé£ Ù░öýÖÇ Û░ÖýØ┤ ýÿñýºü ý©íÙ®┤ÙºîýØ┤ ýòíý▓┤ýºêýåîýÖÇ Ùº×Ùï┐ýòä ÙâëÛ░üÙÉÿÙ®░, ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýùÉ ýé¼ýÜ®ÙÉ£ ýï£ÝÄ©ýØÇ Fig. 2(b)ýÖÇ Û░ÖýØ┤ ýâüÙï¿ Ýæ£Ù®┤Ùºî ýòíý▓┤ýºêýåîýÖÇ Ùº×Ùï┐ýòä ÙâëÛ░üÙÉ£Ùïñ. Ùö░ÙØ╝ýä£ ÙæÉ ýï£ÝÄ© Û░üÛ░üýØÿ ÙâëÛ░ü Ýæ£Ù®┤ýáüÛ│╝ ÙÂÇÝö╝ýØÿ Ù╣äÙÑ╝ Û│äýé░Ýòÿýù¼ Ù╣äÛÁÉÝò£ Ýøä ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿ Û▓░Û│╝ÙÑ╝ ÝåáÙîÇÙí£ ý┤êýáÇýÿ¿ Ùà©ý£ýïñÝùÿýØÿ ÙâëÛ░ü ýï£Û░äýØä Û▓░ýáòÝòÿýÿÇÙïñ. ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿ ýï£ÝÄ©ýØÿ ÙâëÛ░ü Ýæ£Ù®┤ýáüÛ│╝ ÙÂÇÝö╝ Ù╣äÙèö 0.04 mm-1Ùí£, ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿ ýï£ÝÄ©ýØÿ 0.033 mm-1 Ù│┤Ùïñ ýò¢ 1.2Ù░░ Ýü░ Û░ÆýØä Û░ÇýºäÙïñ. Ùö░ÙØ╝ýä£ ýØ┤ÙÑ╝ Û│áÙáñÝòÿýù¼ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýØÿ ýï£ÝÄ©ýØ┤ Ù¬®Ýæ£ýÿ¿ÙÅäýùÉ ÙÅäÙï¼ÝòÿÙèöÙì░ ÝòäýÜöÝò£ ýï£Û░äýØÇ ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýïñÝùÿ Û▓░Û│╝ýùÉ 1.2Ù░░Û░Ç Û│▒Ýò┤ýºä Û░ÆÙ│┤Ùïñ Ýü░ 20ÙÂäý£╝Ùí£ Û▓░ýáòÙÉÿýùêÙïñ.

2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýùÉýä£Ùèö 30 ├ù 100 ├ù 400 cm3 Ýü¼Û©░ýØÿ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè© ýï£ÝÄ©ýØä ýòíý▓┤ýºêýåîýùÉ ýÖäýáäÝ×ê Ùï┤ÛÀ©Û©░ ÙòîÙ¼©ýùÉ ÙâëÛ░ü Ýæ£Ù®┤ýáüÛ│╝ ÙÂÇÝö╝ýØÿ Ù╣äý£¿ýØÇ 0.092 cm-1Ùí£ ý┤êýáÇýÿ¿ ÙâëÛ░üýï£Û░ä ý©íýáò ýï£ÝùÿýØÿ Û░ÆÙ│┤Ùïñ 2.3Ù░░ Ýü░ Û░ÆýØä ÙéÿÝâÇÙé©Ùïñ. ýØ┤ÙÑ╝ Û│áÙáñÝòÿýÿÇýØä Ùòî ÙâëÛ░üýï£Û░äýØÇ ýò¢ 6ÙÂäý£╝Ùí£ Û▓░ýáòÙÉÿýû┤ýò╝ ÝòÿýºÇÙºî, ý┤êýáÇýÿ¿ Ùà©ý£ýØ┤ Ù»©ýä©ÛÀáýù┤ýØ┤ ý£áÙÅäÙÉ£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýùÉ Ù»©ý╣ÿÙèö ýÿüÝûÑýØä Ù│┤Ùïñ ÝÖòýïñÝòÿÛ▓îÝòÿÛ©░ ý£äÝò┤ ÙâëÛ░üýï£Û░äýØÇ ý®ÙÂäÝòÿÛ▓î 1ýï£Û░äý£╝Ùí£ Û▓░ýáòÝòÿýÿÇÙïñ.

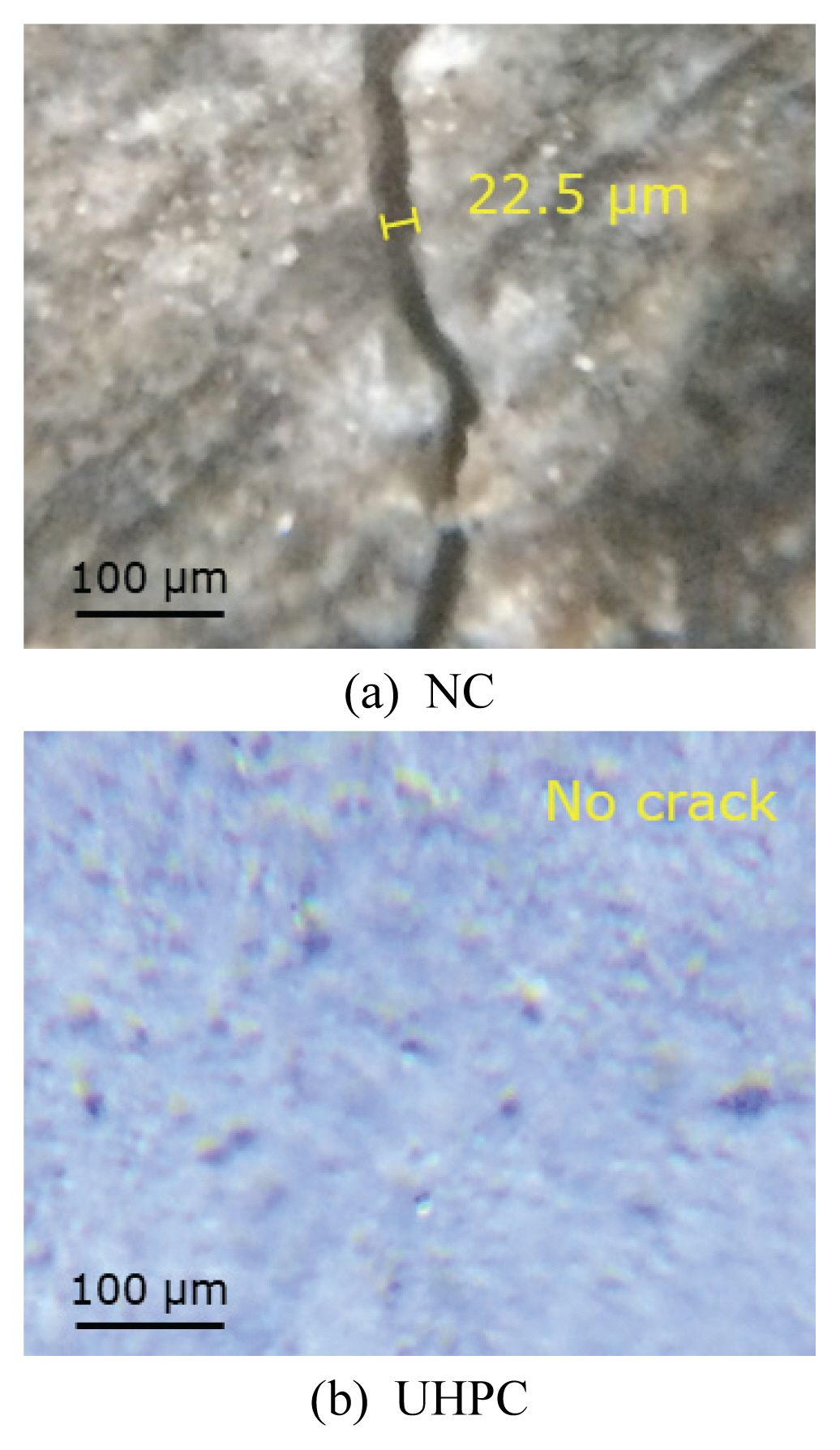

Fig. 5Ùèö ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ 1ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ÛÀáýù┤ Û▒░ÙÅÖýØä ÙéÿÝâÇÙé©Ùïñ. ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©Ùèö 1ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ýñæýòÖÙÂÇýùÉ ýÿ¿ÙÅä Ù│ÇÝÖöýùÉ Ùö░ÙÑ© ýêÿýÂòýØÿ ÛÁ¼ýåìÝÜ¿Û│╝Ùí£ ÙïñýêÿýØÿ Ù»©ýä©ÛÀáýù┤ýØ┤ Ù░£ýâØÝòÿýÿÇý£╝Ù®░, ýÁ£ÙîÇ ÛÀáýù┤ ÝÅ¡ýØÇ 22.5 ÒÄøÙí£ ÝÖòýØ©ÙÉÿýùêÙïñ. ÛÀ©Ùƒ¼Ùéÿ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýùÉýä£Ùèö ýû┤ÙûáÝò£ Ù»©ýä©ÛÀáýù┤ÙÅä Ù░£Û▓¼ÙÉÿýºÇ ýòèýòÿÙïñ. Ùö░ÙØ╝ýä£ 1ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿ Û▓░Û│╝ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© ýÿ¿ÙÅä Ù│ÇÝÖöýØÿ ÛÁ¼ýåìý£╝Ùí£ ýØ©Ýò£ Ù»©ýä©ÛÀáýù┤ Ýÿòýä▒ýØä ýûÁýá£ÝòÿÙ®░, ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî Ùìö ÙéÿýØÇ ÛÀáýù┤ ýáÇÝò¡ ýä▒ÙèÑýØä Ù│┤ýØ┤Ùèö Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ.

ÛÁ¡ÙÂÇýáüýØ© ÙâëÛ░üý£╝Ùí£ ýØ©Ýòÿýù¼ Ù░£ýâØÝòÿÙèö ýØ©ý×Ñ ýØæÙáÑýØÇ ÙæÉ Û░ÇýºÇÙí£, Û│ÁÛÀ╣ Ùé┤ÙÂÇýØÿ Ù¼╝ýØ┤ ýØæÛ▓░ÙÉÿÙ®░ Ù░£ýâØÝòÿÙèö Û▓âÛ│╝ ýÿ¿ÙÅä Ù│ÇÝÖöýùÉ ýØÿÝò£ ÛÁ¼ýåìÝÜ¿Û│╝Ùí£ Ù░£ýâØÝòÿÙèö Û▓âýØ┤Ùïñ. ýØ┤Ùƒ¼Ýò£ ýØ©ý×Ñ ýØæÙáÑýØ┤ ÙºñÝè©Ùª¡ýèñýØÿ ýØ©ý×ÑÛ░òÙÅäÙÑ╝ Ùäÿýû┤ýäñ Ùòî ý¢ÿÝü¼Ùª¼Ýè©ýùÉ Ù»©ýä©ÛÀáýù┤ýØ┤ Ù░£ýâØÝò£Ùïñ. ÙºñÝè©Ùª¡ýèñýØÿ ýØ©ý×ÑÛ░òÙÅäÙèö Ù¼╝-Û▓░Ýò®ý×¼ Ù╣äÛ░Ç ÙåÆýòäýºêýêÿÙíØ Û░ÉýåîÝòÿÙ®░(Tongaroonsri and Tangtermsirikul, 2008; Kogbara et al., 2013), ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Ùé«ýØÇ Ù¼╝-Û▓░Ýò®ý×¼ Ù╣ä(0.20)Ùí£ ýØ©Ýò┤ ÙºñÝè©Ùª¡ýèñýùÉ ý▓½ ÛÀáýù┤ýØ┤ Ù░£ýâØÝòÿÙèö Û░òÙÅäÙèö ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýùÉ Ù╣äÝò┤ ÙåÆÛ▓î ÙéÿÝâÇÙé£Ùïñ(Yoo et al., 2013; Yoo et al., 2016). ÙÿÉÝò£ Û│ÁÛÀ╣ Ùé┤ÙÂÇýØÿ Ù¼╝ýØ┤ ýØæÛ▓░ÙÉÿÙ®░ Ýî¢ý░¢Ýò¿ýùÉ Ùö░ÙØ╝ ÙºñÝè©Ùª¡ýèñýùÉ ÛÀáýù┤ýØ┤ Ù░£ýâØÝòÿÙ»ÇÙí£(Dahmani et al., 2007), ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û│ÁÛÀ╣ÙÑáýØÇ ý┤êýáÇýÿ¿ýùÉýä£ýØÿ ÛÀáýù┤ Ýÿòýä▒ Ù®öý╗ñÙïêýªÿýùÉ ÙºñýÜ░ ýñæýÜöÝò£ ýù¡ÝòáýØä Ýò£Ùïñ. Ùö░ÙØ╝ýä£ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û│ÁÛÀ╣ÙÑáýØ┤ Ùé«ýØäýêÿÙíØ Ù»©ýä©ÛÀáýù┤ ýÿêÙ░®ýùÉ Ùø░ýû┤Ùé£ Û▓âýØä ÝÖòýØ©Ýòá ýêÿ ý×êÙïñ. Teichmann and Schmidt (2004)ýùÉ Ùö░ÙÑ┤Ù®┤ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤Ø Û│ÁÛÀ╣ÙÑáýØÇ ÙÂÇÝö╝Ù╣äÙí£ 15%ýØ┤Ù®░ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤Ø Û│ÁÛÀ╣ÙÑáýØÇ 6%ýØ┤Ùïñ. ÙÿÉÝò£ Rost├ísy et al. (1979)ýÖÇ Rost├ísy et al. (1980)ýùÉ Ùö░ÙÑ┤Ù®┤ ý┤êýáÇýÿ¿ ÙâëÛ░ü ýØ┤Ýøä ýâüýÿ¿ý£╝Ùí£ ÝÜîÙ│ÁÙÉÿÙèö Û│╝ýáòýùÉýä£ ýºüÛ▓¢ýØ┤ 50 nmÙ│┤Ùïñ Ýü░ Û│ÁÛÀ╣ýØÇ Ùé┤ÙÂÇýùÉ ýåÉýâüýØ┤ Ù░£ýâØÝòÿÙ®░ Ýü¼Û©░Û░Ç ý╗ñýºä Ù░ÿÙ®┤ýùÉ, ýºüÛ▓¢ýØ┤ 50 nmÙ│┤Ùïñ ý×æýØÇ Û│ÁÛÀ╣ýØÇ Ýü¼Û©░ýùÉ Ù│ÇÝÖöÛ░Ç ýùåýùêÙïñ. ýªë, Û│ÁÛÀ╣ÙÂäÝżÙèö ý┤êýáÇýÿ¿ýùÉýä£ Ùé┤ÙÂÇ ýåÉýâü ýáÇÝò¡ ýä▒ÙèÑýùÉ Ýü░ ýÿüÝûÑýØä Ù»©ý╣ÿÙèö Û▓âý£╝Ùí£ ÝîÉÙï¿Ýòá ýêÿ ý×êÙïñ. ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û│ÁÛÀ╣ýØÇ ýú╝Ùí£ 10~30 nmýùÉ ÙÂäÝżÝòÿÙèö Ù░ÿÙ®┤ýùÉ, ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û│ÁÛÀ╣ýØÇ 100~150 nmýùÉ ÙÂäÝżÝò£Ùïñ(Chan et al., 2000; Rougeau and Borys, 2004). ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ýØ┤Ùƒ¼Ýò£ Û│ÁÛÀ╣ ÙÂäÝżÙèö Ù░░Ýò®ýùÉ ýé¼ýÜ®ÙÉ£ Ù»©ýä©Ýò£ ý×àý×ÉýØÿ ýïñÙª¼ý╣┤Ýô©ýØ┤ ÙºñÝè©Ùª¡ýèñýØÿ Ù╣ê Û│ÁÛ░äýØä Ù░ÇýïñÝòÿÛ▓î ý▒äýøîýú╝Û©░ ÙòîÙ¼©ýØ┤Ùïñ(Rougeau and Borys, 2004). Ùö░ÙØ╝ýä£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýØ╝Ù░ÿý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýù¼ ý┤êýáÇýÿ¿ ÝÖÿÛ▓¢ Ùà©ý£ýùÉ ýØÿÝò£ Ù»©ýä©ÛÀáýù┤ Ýÿòýä▒ýùÉ Ùìö ÙéÿýØÇ ýáÇÝò¡ ýä▒ÙèÑýØä ÙéÿÝâÇÙé┤Ùèö Û▓âý£╝Ùí£ ÝîÉÙï¿ÙÉ£Ùïñ.

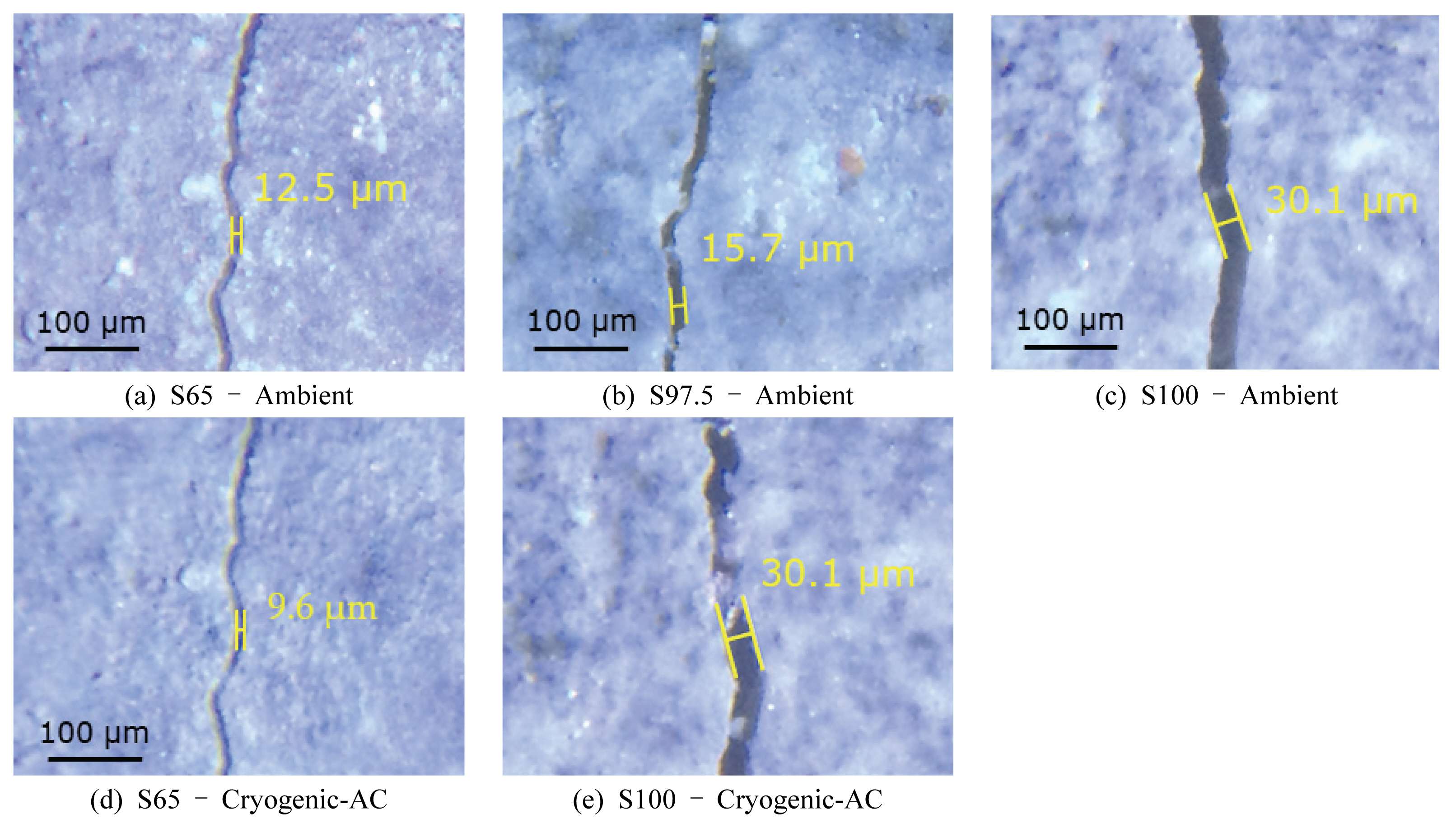

Fig. 6ýØÇ 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ÛÀáýù┤ Û▒░ÙÅÖýØä Ù│┤ýù¼ýñÇÙïñ. ýâüýÿ¿ýùÉýä£ Ù»©ýä©ÛÀáýù┤ ý£áÙÅäÙÑ╝ ý£äÝò£ ýé¼ýáäÝòÿýñæ ýáüýÜ® ýØ┤Ýøä S65 ýï£ÝÄ©ýØÿ ýÁ£ÙîÇ Ù»©ýä©ÛÀáýù┤ ÝÅ¡ýØÇ 12.5 ÒÄøÙí£ ÝÖòýØ©ÙÉÿýùêý£╝Ù®░, S97.5 Ù░Å S100 ýï£ÝÄ©ýØÇ Û░üÛ░ü 15.7 ÒÄøÛ│╝ 30.1 ÒÄøý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ. ýé¼ýÜ®ÙÉ£ Û░òýä¼ý£áýØÿ ÝÿòýâüÙ╣äÛ░Ç ýªØÛ░ÇÝòáýêÿÙíØ Ù»©ýä©ÛÀáýù┤ýØÿ ýÁ£ÙîÇ ÝÅ¡ýØ┤ ýªØÛ░ÇÝòÿÙèö Û▓¢ÝûÑýØä Ù│┤ýØ┤Ù®░, ýØ┤Ùèö ýé¼ýáäýùÉ Ù»©ýä©ÛÀáýù┤ýØä ý£áÙÅäÝòÿÛ©░ ý£äÝò┤ ýáüýÜ®Ýò£ ÝòÿýñæýùÉ ýØÿÝò┤ Ù░£ýâØÝò£ ý×öýù¼ ý▓ÿýºÉ Û░ÆýùÉ Ùö░ÙÑ© Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉ£Ùïñ. Û░ü ýä¼ý£á Ù│ÇýêÿÙ│ä ý×öýù¼ ý▓ÿýºÉ Û░ÆýØÇ S65, S97.5, S100 ýê£ýä£Ùí£ Û░üÛ░ü 0.15, 0.43, 0.62 mmýØ┤Ù®░, S100 ýï£ÝÄ©ýØÿ ý×öýù¼ ý▓ÿýºÉ Û░ÆýØÇ S65ýï£ÝÄ©ýØÿ ý×öýù¼ ý▓ÿýºÉ Û░ÆÛ│╝ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ýò¢ 4Ù░░Û░ÇÙƒë Ýü░ Û░ÆýØä Ù│┤ýØ©Ùïñ.

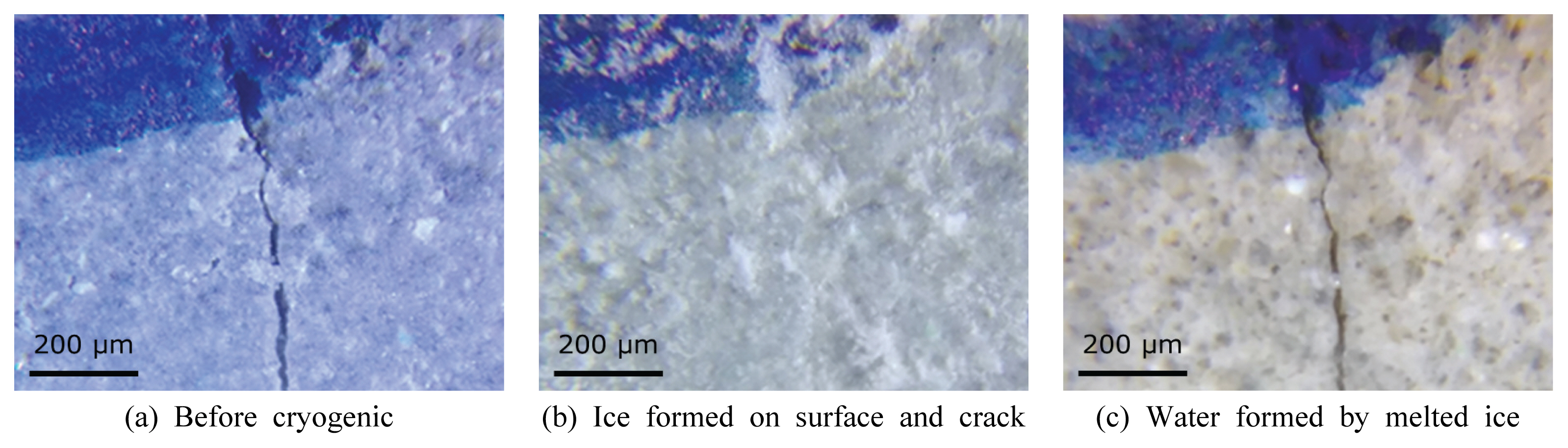

2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ÙÅÖýØ╝Ýò£ Ù»©ýä©ÛÀáýù┤ýØä Û┤Çý░░ÝòÿýÿÇýØä Ùòî ÛÀáýù┤ ÝÅ¡ýØÿ Û░Éýåî ÝÿäýâüýØä ÝÖòýØ©ÝòÿýÿÇÙïñ. Figs. 6(d) and (e)Ùèö S65 ýï£ÝÄ©Û│╝ S100 ýï£ÝÄ©ýØÿ 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä 3ýØ╝ ÙÅÖýòêýØÿ Û©░Û▒┤ ýûæýâØ ýØ┤Ýøä Ù»©ýä©ÛÀáýù┤ýØä ÙéÿÝâÇÙé┤ÙèöÙì░, S65 ýï£ÝÄ©ýØÿ Ù»©ýä©ÛÀáýù┤ýØÇ 9.6 ÒÄøÙí£ Û░ÉýåîÝò£ Ù░ÿÙ®┤ S100 ýï£ÝÄ©ýØÿ Ù»©ýä©ÛÀáýù┤ýØÇ Ýü░ Ù│ÇÝÖöÙÑ╝ Ù│┤ýØ┤ýºÇ ýòèÙèöÙïñ. S65ýï£ÝÄ©ýØÿ Ù»©ýä©ÛÀáýù┤ ÝÅ¡ Û░Éýåî ÝÿäýâüýØÇ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ýâüýÿ¿ýùÉýä£ ýÿ¿ÙÅäÙÑ╝ ÝÜîÙ│ÁÝò¿ýùÉ Ùö░ÙØ╝ Ýæ£Ù®┤ýùÉ ýØæÛ▓░ÙÉÿÙèö ýä▒ýùÉÛ░Ç Ùà╣ýØîý£╝Ùí£ýì¿ ýâØýä▒ÙÉ£ Ù¼╝ýùÉ ýØÿÝò┤ Ù░£ýâØÝò£ ý×ÉÛ©░ ý╣ÿý£á ÝÿäýâüýùÉ ýØÿÝò£ Û▓âý£╝Ùí£ ýØ┤Ùƒ¼Ýò£ Û│╝ýáòýØÇ Fig. 7ýùÉ ýâüýä©Ý×ê ÙéÿÝâÇÙéÿý×êÙïñ. Fig. 7(b)ýùÉ Ù│┤ýØ┤Ùèö Ù░öýÖÇ Û░ÖýØ┤ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ýâüýÿ¿ý£╝Ùí£ ÝÜîÙ│ÁÙÉ¿ýùÉ Ùö░ÙØ╝ ýï£ÝÄ© Ýæ£Ù®┤ Ù░Å Ù»©ýä©ÛÀáýù┤ýùÉ ýû╝ýØîýØ┤ Ýÿòýä▒ÙÉÿÙèö Û▓âýØä ÝÖòýØ© Ýòá ýêÿ ý×êýùêÙïñ. ýØ┤Ùƒ¼Ýò£ ýû╝ýØîýØÇ ýâüýÿ¿ýùÉýä£ ýï£Û░äýØ┤ ýºÇÙé¿ýùÉ Ùö░ÙØ╝ Ù¼╝Ùí£ Ùà╣ýòä ýï£ÝÄ©ýØÿ ý×ÉÛ©░ý╣ÿý£áÛ░Ç Û░ÇÙèÑÝòÿÛ▓î Ýò£ Û▓âý£╝Ùí£ ÝîÉÙï¿ÙÉ£Ùïñ. Edvardsen (1999)ýùÉ Ùö░ÙÑ┤Ù®┤ ÛÀáýù┤ýØÿ ý×ÉÛ©░ý╣ÿý£á ýåìÙÅäÙèö ÛÀáýù┤ ÝÅ¡ýùÉ ýÿüÝûÑýØä Ù░øý£╝Ù®░, ÙäôýØÇ ÛÀáýù┤ýØ╝ýêÿÙíØ ý×ÉÛ©░ý╣ÿý£áýùÉ Ùìö ÙºÄýØÇ ýï£Û░äýØä ÝòäýÜöÙí£ Ýò£Ùïñ. Ùö░ÙØ╝ýä£ ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýòÿýù¼ Ù¼╝ýùÉ Ùà©ý£ÙÉÿÙèö ýººýØÇ ýï£Û░äÙÅÖýòê S65 ýï£ÝÄ©ýØÿ ýóüýØÇ Ù»©ýä©ÛÀáýù┤ÙºîýØ┤ ý╣ÿý£áÙÉ£ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿÙ®░, S65 Û░òýä¼ý£áÙÑ╝ ýé¼ýÜ®ÝòÿýÿÇýØä Ùòî ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýò£ Ù»©ýä©ÛÀáýù┤ýØÿ ý╣ÿý£áÛ░Ç Û░ÇÙèÑÝò£ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ.

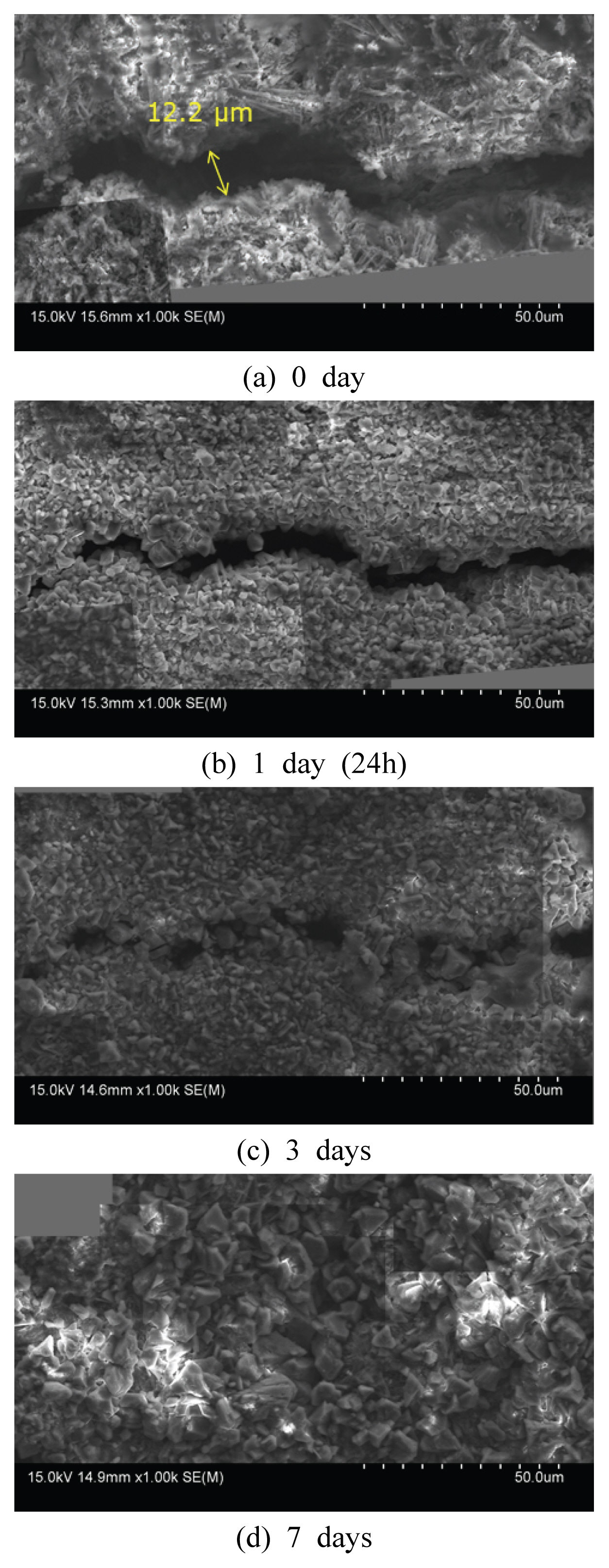

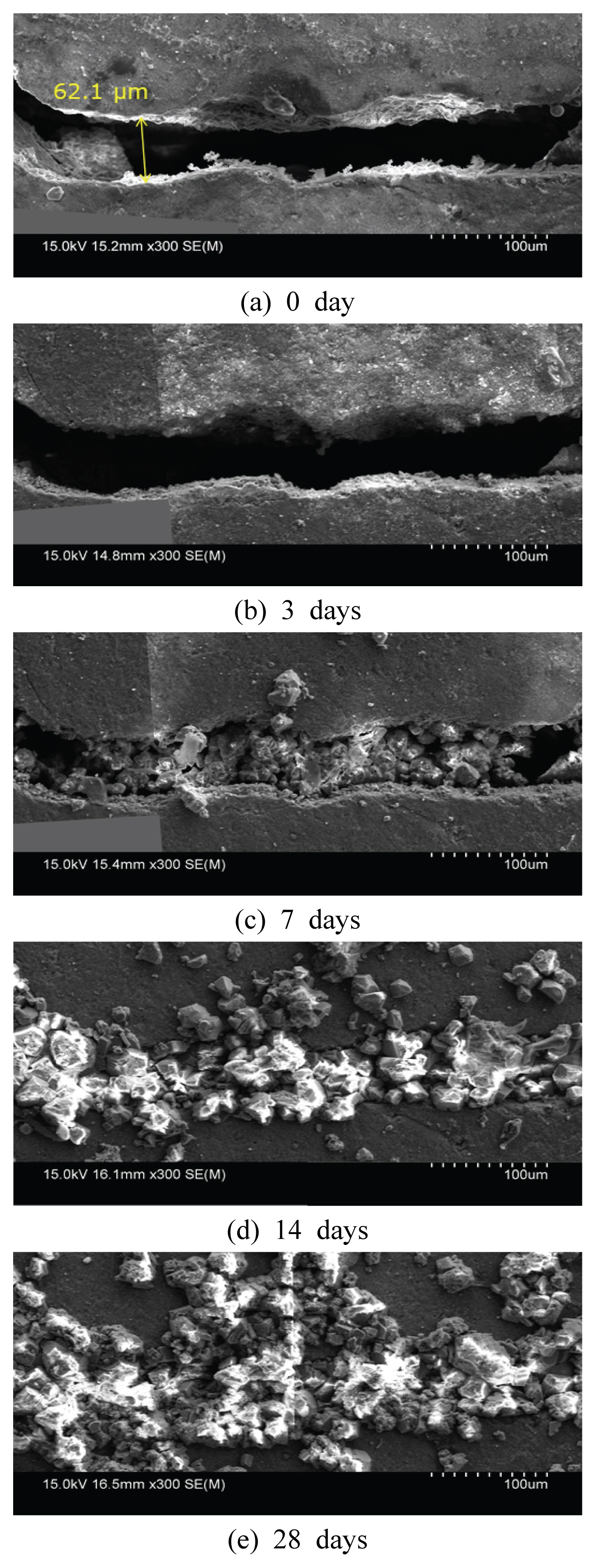

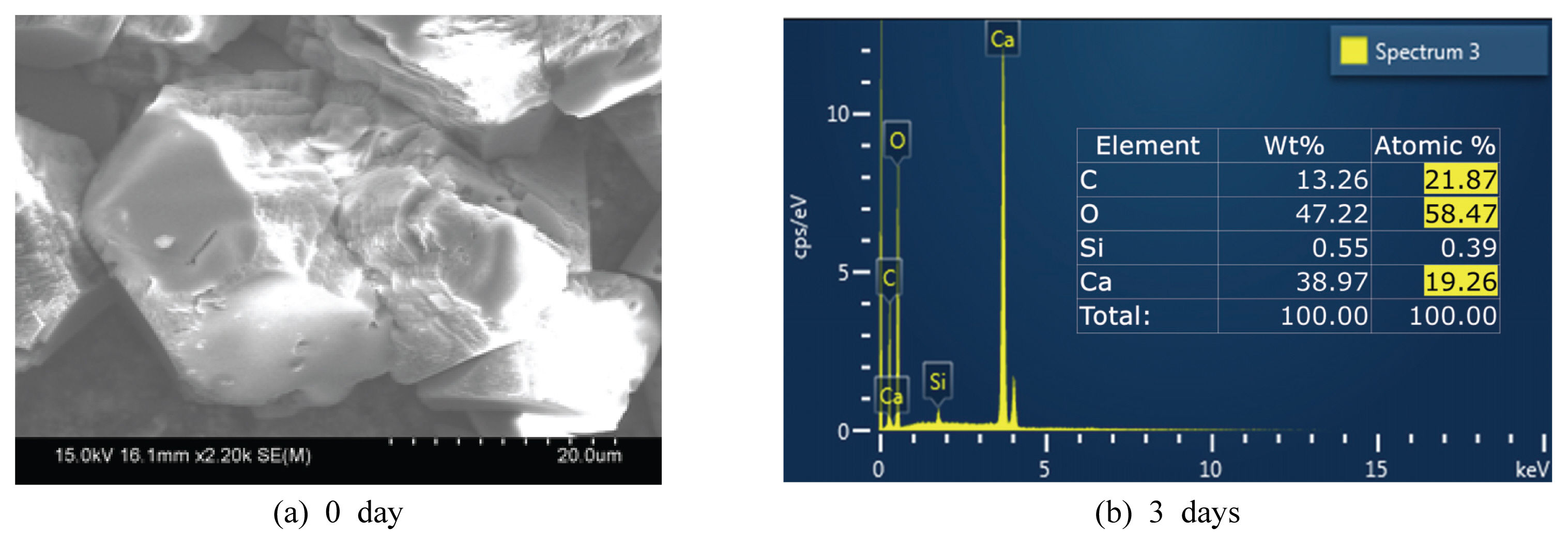

ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä SEM-EDX ÙÂäýäØýØä ÝåÁÝò┤ 28ýØ╝ýØÿ ýêÿýñæýûæýâØÛ©░Û░ä ÙÅÖýòê ÛÀáýù┤ ÝÅ¡ýØ┤ ÙïñÙÑ© ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý×ÉÛ©░ý╣ÿý£á ýä▒ÙèÑýØä ÝÅëÛ░ÇÝòÿýÿÇÙïñ. 12.2 ÒÄøýØÿ Ù»©ýä©ÛÀáýù┤Û│╝ 62.1 ÒÄø Ù»©ýä©ÛÀáýù┤ýØä 0, 1, 3, 7, 14, 28ýØ╝ÙÅÖýòê ýêÿýñæýûæýâØýØä ýºäÝûëÝòÿÙ®░ Û┤Çý░░ÝòÿýÿÇý£╝Ù®░ Û▓░Û│╝Ùèö Figs. 8 and 9ýùÉ ÙéÿÝâÇÙé┤ýùêÙïñ. Fig. 8ýùÉýä£ Ù│┤ýØ┤Ùèö Ù░öýÖÇ Û░ÖýØ┤ 12.2 ÒÄøýØÿ ýóüýØÇ Ù»©ýä©ÛÀáýù┤ýØÇ Ùï¿ ÝòÿÙú¿ýØÿ ýêÿýñæýûæýâØýØä ÝåÁÝò┤ ÛÀáýù┤ý▒äýøÇÙ¼╝ýºêÙí£ Ù╣áÙÑ┤Û▓î ý▒äýøîýºÇÙèö Û▓âýØä ÝÖòýØ© Ýòá ýêÿ ý×êý£╝Ù®░, 3ýØ╝ýØÿ ýêÿýñæýûæýâØ ýØ┤Ýøä Ù»©ýä©ÛÀáýù┤ýØÿ ÙîÇÙÂÇÙÂäýØ┤ ÛÀáýù┤ý▒äýøÇÙ¼╝ýºêÙí£ ý▒äýøîýºä Û▓âýØä ÝÖòýØ©Ýòá ýêÿ ý×êÛ│á, 7ýØ╝ýØÿ ýêÿýñæýûæýâØ ýØ┤Ýøä Ù»©ýä©ÛÀáýù┤ýØ┤ Ù¬¿ÙæÉ ý▒äýøîýºä Û▓âýØä ÝÖòýØ©Ýòá ýêÿ ý×êÙïñ. Ù░ÿÙ®┤ýùÉ Fig. 9ýØÿ Ù╣äÛÁÉýáü ÙäôýØÇ 62.1 ÒÄøýØÿ Ù»©ýä©ÛÀáýù┤ýØÇ 3ýØ╝ýØÿ ýêÿýñæýûæýâØ ýØ┤ÝøäýùÉ Ýü░ Ù│ÇÝÖöÙÑ╝ Ù│┤ýØ┤ýºÇ ýòèý£╝Ù®░, 7ýØ╝ýØÿ ýêÿýñæýûæýâØ ýØ┤Ýøä ÛÀáýù┤ý▒äýøÇÙ¼╝ýºêÙí£ Ù»©ýä©ÛÀáýù┤ýØ┤ ýØ╝ÙÂÇ ý▒äýøîýºä Û▓âýØä ÝÖòýØ©Ýòá ýêÿ ý×êÛ│á, ýÁ£ýóàýáüý£╝Ùí£ 28ýØ╝ýØÿ ýêÿýñæýûæýâØ ýØ┤Ýøä ÛÀáýù┤ýØ┤ Ù¬¿ÙæÉ ý▒äýøîýºä Û▓âýØä ÝÖòýØ©ÝòÿýÿÇÙïñ. Ùö░ÙØ╝ýä£ ýêÿýñæýûæýâØýØä ÝåÁÝò£ ÛÀáýù┤ý▒äýøÇ ÝÿäýâüýØÇ ÛÀáýù┤ ÝÅ¡ýùÉ Ýü░ ýÿüÝûÑýØä Ù░øÙèö Û▓âýØä ÝÖòýØ©Ýòá ýêÿ ý×êýùêý£╝Ù®░, ýóüýØÇ Ù»©ýä©ÛÀáýù┤ýØ┤ ÙäôýØÇ Ù»©ýä©ÛÀáýù┤Ù│┤Ùïñ Ùìö Ù╣áÙÑ┤Û▓î ý▒äýøîýºÇÙèö Û▓âýØä ÝÖòýØ©Ýòá ýêÿ ý×êýùêÙïñ.

Ù»©ýä©ÛÀáýù┤ýùÉ ýâêÙí¡Û▓î Ýÿòýä▒ÙÉ£ ÛÀáýù┤ý▒äýøÇÙ¼╝ýºêýØä ÛÀ£Ù¬àÝòÿÛ©░ ý£äÝò┤ Ýò┤Ùï╣ ýï£ÝÄ©ýùÉ EDX ÙÂäýäØýØä ýºäÝûëÝòÿýÿÇý£╝Ù®░ Û▓░Û│╝Ùèö Fig. 10ýùÉ ÙéÿÝâÇÙé┤ýùêÙïñ. ÛÀáýù┤ý▒äýøÇÙ¼╝ýºêýØÇ ýú╝Ùí£ Ýâäýåî(C)ýÖÇ ýé░ýåî(O), ý╣╝ýèÿ(Ca)ý£╝Ùí£ ÛÁ¼ýä▒ÙÉÿýû┤ ý×êý£╝Ù®░, ýØ┤ÙôñýØÿ ýøÉý×É ÛÁ¼ýä▒ Ù╣äý£¿ýØÇ Û░üÛ░ü 21.87:58.47:19.26ý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ. ýØ┤Ùƒ¼Ýò£ ýøÉý×É ÛÁ¼ýä▒ Ù╣äý£¿ýØÇ Ýâäýé░ý╣╝ýèÿ(CaCO3)ýØÿ 20:60:20Û│╝ ÙºñýÜ░ ý£áýé¼Ýò£ Û░ÆýØä Ù│┤ýØ┤Û©░ ÙòîÙ¼©ýùÉ ÛÀáýù┤ý▒äýøÇÙ¼╝ýºêýØÇ Ýâäýé░ý╣╝ýèÿý£╝Ùí£ ÝîÉÙ¬àÙÉÿýùêÙïñ. ýØ┤Ùƒ¼Ýò£ Û▓░Û│╝Ùèö Edvardsen (1999)ýÖÇ Homma et al. (2009), Kwon et al. (2013)ýØÿ ýù░ÛÁ¼Û▓░Û│╝ýÖÇ ýØ╝ý╣ÿÝò£Ùïñ.

Edvardsen (1999)Ùèö ÛÀáýù┤ Ùé┤ÙÂÇýùÉýä£ Ýâäýé░ý╣╝ýèÿýØÿ Ýÿòýä▒ýØÇ ý×ÉÛ©░ý╣ÿý£á ÝÿäýâüýØÿ Û▒░ýØÿ ý£áýØ╝Ýò£ ýøÉýØ©ýØ┤ÙØ╝Û│á ýû©Û©ëÝòÿýÿÇý£╝Ù®░, ýòäÙ×ÿ Eqs. (1) ~ (3)Û│╝ Û░ÖýØ┤ Ù¼╝ýØ┤ Ù░ÿýØæÝòÿýù¼ Ýâäýé░ý╣╝ýèÿýØ┤ Ýÿòýä▒ÙÉÿÙèö ÝÖöÝòÖÙ░ÿýØæ Ù®öý╗ñÙïêýªÿýØä ýá£ýï£ÝòÿýÿÇÙïñ.

ÙîÇÛ©░ ýñæýØÿ ýØ┤ýé░ÝÖöÝâäýåîÛ░Ç Ù¼╝ýùÉ Ùà╣ý£╝Ù®┤ Ýâäýé░ýù╝(CO32-)Û│╝ Ýâäýé░ýêÿýåîýù╝(HCO3-)ýØ┤ Ýÿòýä▒ÙÉ£Ùïñ. ÛÀáýù┤Ù®┤ýØä Ùö░ÙØ╝ ýí┤ý×¼ÝòÿÙèö ýêÿýé░ÝÖöý╣╝ýèÿ(Ca(OH)2)ýùÉýä£ ý×Éý£á ý╣╝ýèÿ ýØ┤ýÿ¿ýØ┤ Ù░®ý£ÙÉÿÛ│á, Ýâäýé░ýù╝Û│╝ Ýâäýé░ýêÿýåîýù╝ýØ┤ ýØ┤ýÖÇ Ù░ÿýØæÝòÿÙ®┤ Ùºêý╣¿Ùé┤ Ýâäýé░ý╣╝ýèÿ(CaCO3)ýØ┤ Ýÿòýä▒ÙÉ£Ùïñ.

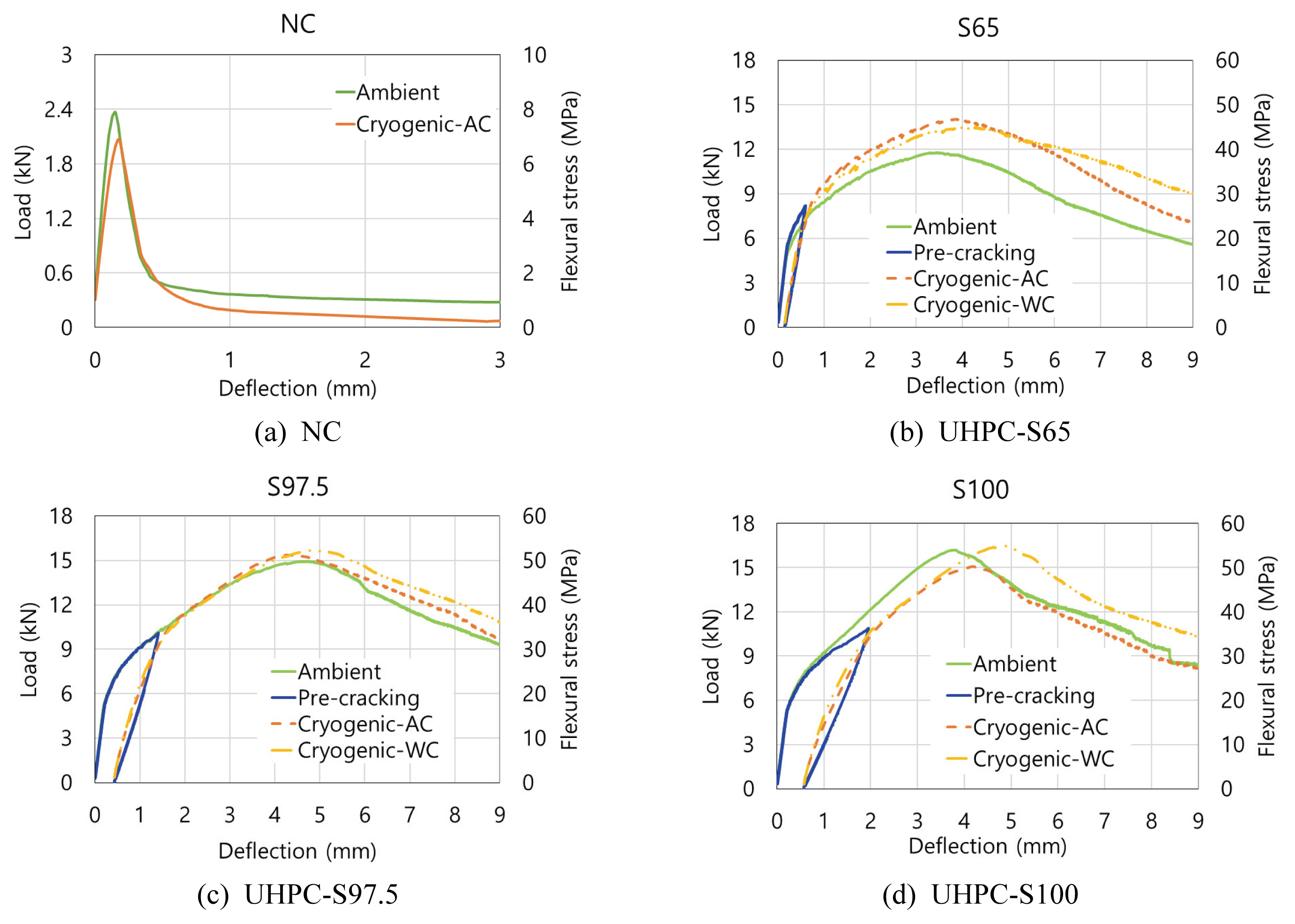

Fig. 11ýØÇ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û░üÛ░ü ýí░Û▒┤(Ambient, Cryogenic-AC, Cryogenic-WC) ýòäÙ×ÿýùÉýä£ 4ýáÉ Ý£¿ ýïñÝùÿýùÉ Ùö░ÙÑ© Ýòÿýñæ-Ù│Çý£ä Û│íýäáýØä ÙéÿÝâÇÙé©Ùïñ. ýâüýÿ¿ýùÉýä£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ýé¼ýÜ®ÙÉ£ Û░òýä¼ý£áýØÿ ýóàÙÑÿýÖÇ Û┤ÇÛ│äýùåýØ┤ ÙºñýÜ░ Ùø░ýû┤Ùé£ Û▓âý£╝Ùí£ ÙéÿÝâÇÙé¼Ùïñ. Ýè╣Ý×ê ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ÙºñýÜ░ Ùé«ýØÇ Ù¼╝-Û▓░Ýò®ý×¼ Ù╣äÙí£ ýØ©Ýòÿýù¼ ýï£Ù®ÿÝè© ÙºñÝè©Ùª¡ýèñ Û░òÙÅäÛ░Ç ÙåÆÛ│á, Û░òýä¼ý£áýØÿ Ýÿ╝ý×àý£╝Ùí£ ýØ©Ýòÿýù¼ ÙºñýÜ░ ÙåÆýØÇ Ý£¿ Û░òÙÅäÙÑ╝ ÙéÿÝâÇÙé┤ýùêÙïñ.

ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û▓¢ýÜ░ ý▓½ ÛÀáýù┤ Ù░£ýâØ ýØ┤Ýøä Ý£¿ Û░òÙÅäÛ░Ç Û©ëÛ▓®Ý×ê Û░ÉýåîÝòÿÙèöÙì░, ýØ┤Ùèö ýä¼ý£áÛ░Ç Ýÿ╝ý×àÙÉÿýºÇ ýòèýòä ýØ©ý×Ñ ýáÇÝò¡ ýä▒ÙèÑýØä ÙéÿÝâÇÙé┤ýºÇ ýòèÛ©░ ÙòîÙ¼©ýØ┤Ùïñ. ÛÀ©Ùƒ¼Ùéÿ ýÖäýáäÝ×ê Û░òÙÅäÛ░Ç 0 Û░Æý£╝Ùí£ Û░ÉýåîÝòÿÙèö ÙºñýÜ░ Û©ëÛ▓®Ýò£ ÝîîÛ┤┤Ùèö Ù│┤ýØ┤ýºÇ ýòèýòÿÙèöÙì░, ýØ┤Ùèö ÛÁÁýØÇ Û│¿ý×¼ýØÿ Û│¿ý×¼ Ùº×Ù¼╝Ùª╝ Ýÿäýâü ÙòîÙ¼©ýØ┤Ùïñ. ÙÿÉÝò£ ýØ╝Ù░ÿý¢ÿÝü¼Ùª¼Ýè©ýØÿ 1ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä Ý£¿ ýä▒ÙèÑ Û░ÉýåîÙÑ╝ ÝÖòýØ© Ýòá ýêÿ ý×êýùêý£╝Ù®░ ýØ┤Ùèö ýò×ýä£ ýû©Û©ëÝò£ Ù░öýÖÇ Û░ÖýØ┤ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä Ù»©ýä©ÛÀáýù┤ýØ┤ Ù░£ýâØÝòÿýÿÇÛ©░ ÙòîÙ¼©ýØ┤Ùïñ.

UHPCýØÿ Û▓¢ýÜ░ ýé¼ýÜ®ÙÉ£ Û░òýä¼ý£áýØÿ ýóàÙÑÿýùÉ Ùö░ÙØ╝ Ý£¿ ýä▒ÙèÑýØ┤ ÙïñÙÑ┤Û▓î ÙéÿÝâÇÙé¼Ùïñ. S65 ýä¼ý£áÛ░Ç ýé¼ýÜ®ÙÉ£ UHPCýØÿ Ý£¿ ýä▒ÙèÑýØ┤ Û░Çý×Ñ Ùé«ýØÇ Û▓âý£╝Ùí£ ÙéÿÝâÇÙé¼Û│á, S100 ýä¼ý£áÛ░Ç ýé¼ýÜ®ÙÉ£ UHPCýØÿ Ý£¿ ýä▒ÙèÑýØ┤ Û░Çý×Ñ ÙåÆýØÇ Û▓âý£╝Ùí£ ÝÖòýØ© ÙÉÿýùêÙïñ. MS ýä¼ý£áÛ░Ç ýé¼ýÜ®ÙÉ£ ýïñÝùÿý▓┤ýØÿ Ý£¿ Û░òÙÅäÙèö SS ýä¼ý£á ýïñÝùÿý▓┤Ù│┤Ùïñ Ýü¼Û│á LS ýä¼ý£á ýïñÝùÿý▓┤Ù│┤Ùïñ ý×æýØÇ Û▓âý£╝Ùí£ ÝÖòýØ© ÙÉÿýùêÙïñ. ýØ┤Ùƒ¼Ýò£ Û▓░Û│╝ýØÿ ýøÉýØ©ýØÇ ýé¼ýÜ®ÙÉ£ Û░òýä¼ý£áýØÿ ÝÿòýâüÙ╣ä(Lf/df)Û░Ç ÙïñÙÑ┤Û©░ ÙòîÙ¼©ýØ┤Ùïñ. ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ÛÀáýù┤ ýØ┤Ýøä ýÁ£ÙîÇÛ░òÙÅäÙèö ýä¼ý£áýØÿ ÝÿòýâüÙ╣äýÖÇ Ýÿ╝ý×àÙÑáýùÉ ýØÿÝò┤ Û▓░ýáòÙÉ£ÙïñÛ│á ýòîÙáñýíîý£╝Ù®░, ÙïñýØî Eq. (4)ýÖÇ Û░ÖÙïñ.

ýù¼Û©░ýä£ ¤âpcÙèö ÛÀáýù┤ ýØ┤Ýøä ýÁ£ÙîÇ Ý£¿ ýØæÙáÑýØä ÙéÿÝâÇÙé┤Ù®░, ╬╗Ùèö Û░òýä¼ý£áýØÿ ÙÂäýé░ýä▒Û│╝ Ù░®ÝûÑýä▒, Ù¡ëý╣¿ Ýÿäýâü Ùô▒ýØä Û│áÙáñÝò£ Û│äýêÿýØ┤Ù®░, ¤äÙèö Û░òýä¼ý£áýØÿ ÙÂÇý░®ýØæÙáÑýØä, VfÙèö Û░òýä¼ý£áýØÿ Ýÿ╝ý×àÙÑáýØä, LfÙèö Û░òýä¼ý£áýØÿ Û©©ýØ┤ÙÑ╝, dfÙèö Û░òýä¼ý£áýØÿ ýºüÛ▓¢ýØä ÙéÿÝâÇÙé©Ùïñ. Ù│© ýïñÝùÿýùÉ ýé¼ýÜ®ÙÉ£ Û░òýä¼ý£áýØÿ Ýÿ╝ý×àÙÑáýØÇ Ù¬¿ÙæÉ 2%Ùí£ Û░Öý£╝Ù®░, Ù¬¿Ùôá Û░òýä¼ý£áÛ░Ç Û│áÙÑ┤Û▓î ý×ÿ ÙÂäýé░ÙÉÿýùêÙïñÛ│á Û░ÇýáòÝòÿýÿÇýØä Ùòî ÛÀáýù┤ ýØ┤Ýøä ýÁ£ÙîÇ Ý£¿ Û░òÙÅäÙÑ╝ Û▓░ýáòÝòÿÙèö Û▓âýØÇ Û░òýä¼ý£áýØÿ ÝÿòýâüÙ╣ä(Lf/df)ýØ┤Ùïñ. ýªë, ýä¼ý£áýØÿ ÝÿòýâüÙ╣äÛ░Ç Û░Çý×Ñ ÙåÆýØÇ S100 ýä¼ý£áÛ░Ç Ý£¿ ýä▒ÙèÑ Ù®┤ýùÉýä£ Û░Çý×Ñ Ùø░ýû┤Ùé£ ýä¼ý£áÙí£ ÝÖòýØ©ÙÉÿýùêÙïñ.

UHPCýØÿ 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä Û▒░ÙÅÖ ÙÿÉÝò£ Û░òýä¼ý£áýØÿ ýóàÙÑÿýùÉ Ùö░ÙØ╝ ÙïñÙÑ┤Û▓î ÙéÿÝâÇÙé¼Ùïñ. Cryogenic-AC ýí░Û▒┤ ýòäÙ×ÿýùÉýä£ S65 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ Ý£¿ ýä▒ÙèÑýØÇ Ýü¼Û▓î ýªØÛ░ÇÝò£ Ù░ÿÙ®┤ýùÉ S97.5 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ Ý£¿ ýä▒ÙèÑýØÇ Ýü░ ý░¿ýØ┤ÙÑ╝ Ù│┤ýØ┤ýºÇ ýòèýòÿý£╝Ù®░, S100 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ Ý£¿ ýä▒ÙèÑýØÇ Ýü¼Û▓î Û░Éýåî Ýò£ Û▓âýØä ÝÖòýØ© Ýòá ýêÿ ý×êÙïñ. ýØ┤Ùƒ¼Ýò£ Û▓░Û│╝Ùèö 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿýØä ýºäÝûë Ýòá Ùòî ýé¼ýáäýùÉ ý£áÙÅäÙÉ£ Ù»©ýä©ÛÀáýù┤ýùÉ Ùö░ÙÑ© Û▓âý£╝Ùí£ ÝîÉÙï¿ÙÉÿÙ®░, ýò×ýä£ ýû©Û©ëÝò£ Ù░öýÖÇ Û░ÖýØ┤ ý×öÙÑÿ ý▓ÿýºÉ Û░ÆýØÿ ý░¿ýØ┤Ùí£ ýØ©Ýò£ Ù»©ýä©ÛÀáýù┤ ÝÅ¡ýØÿ ý░¿ýØ┤Û░Ç 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ ýÿüÝûÑýØä ýñÇ Û▓âý£╝Ùí£ ÝîÉÙï¿ÙÉ£Ùïñ. ýÁ£ÙîÇ ÛÀáýù┤ ÝÅ¡ýØ┤ Û░Çý×Ñ ýóüÛ│á ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ÛÀáýù┤ ÝÅ¡ Û░Éýåî ÝÿäýâüýØä ÝÖòýØ©Ýò£ S65 ýï£ÝÄ©ýØÇ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ý×ÉÛ©░ý╣ÿý£á Ýÿäýâüý£╝Ùí£ ýØ©Ýòÿýù¼ Ý£¿ ýä▒ÙèÑýØÿ ÝûÑýâüýØ┤ ýØ┤Ùú¿ýû┤ýºä Û▓âý£╝Ùí£ Ù│╝ ýêÿ ý×êý£╝Ù®░, S100 ýï£ÝÄ©ýØÇ ÙäôýØÇ Ù»©ýä©ÛÀáýù┤ýØ┤ ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ ýØÿÝò£ ýåÉýâüýØä ÙìöýÜ▒ ýï¼Û░üÝòÿÛ▓î Ýòÿýù¼ Ý£¿ ýä▒ÙèÑ Û░ÉýåîÙí£ ýØ┤ýû┤ýºä Û▓âýØä ÝÖòýØ© Ýòá ýêÿ ý×êÙïñ. UHPCýØÿ 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä 28ýØ╝ ÙÅÖýòê ýêÿýñæýûæýâØýØä ýºäÝûëÝò£ ýï£ÝÄ©(Cryogenic-WC)ýØÿ Ý£¿ ýä▒ÙèÑýØÇ Û©░ýí┤ ýâüýÿ¿ýùÉýä£ýØÿ Ý£¿ ýä▒ÙèÑÛ│╝ ÙÅÖýØ╝ÝòÿÛ▒░Ùéÿ ÙåÆýØÇ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ. ýØ┤Ùƒ¼Ýò£ Û▓░Û│╝Ùèö SEM ÙÂäýäØ Û▓░Û│╝Ùí£ ÝÖòýØ©Ýò£ Ù░öýÖÇ Û░ÖýØ┤ 28ýØ╝ýØÿ ýêÿýñæýûæýâØýØä ÝåÁÝò┤ Ù»©ýä©ÛÀáýù┤ýØ┤ Ù░Å ý┤êýáÇýÿ¿ýùÉ ýØÿÝò£ ýåÉýâüýØ┤ Ù¬¿ÙæÉ ÝÜîÙ│ÁÙÉÿýùêÛ©░ ÙòîÙ¼©ýØ┤Ùïñ.

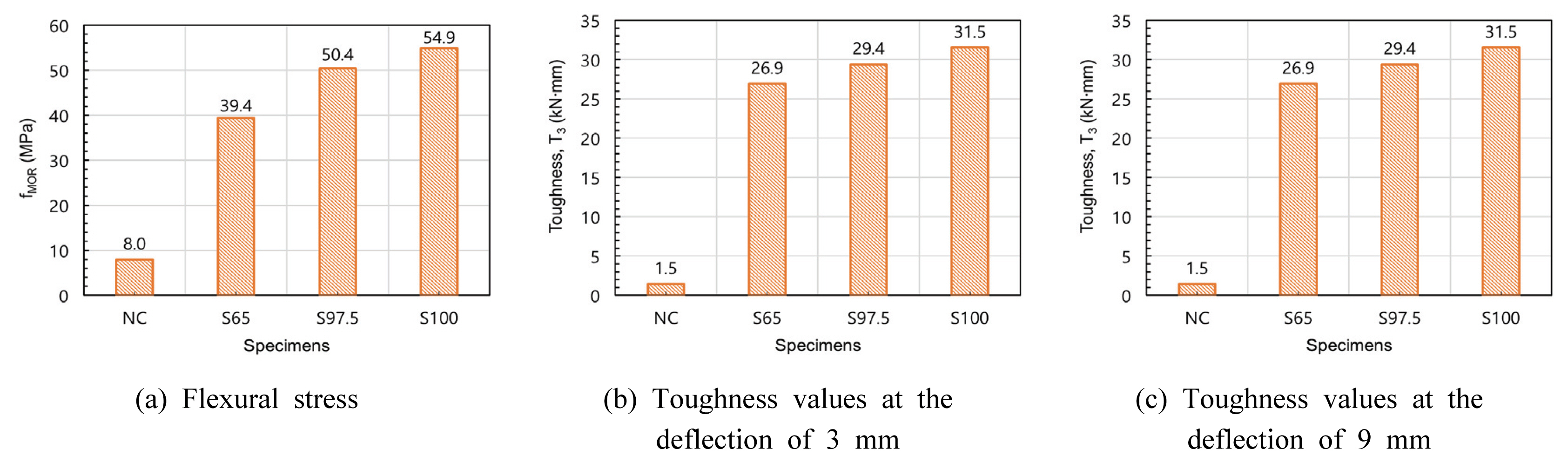

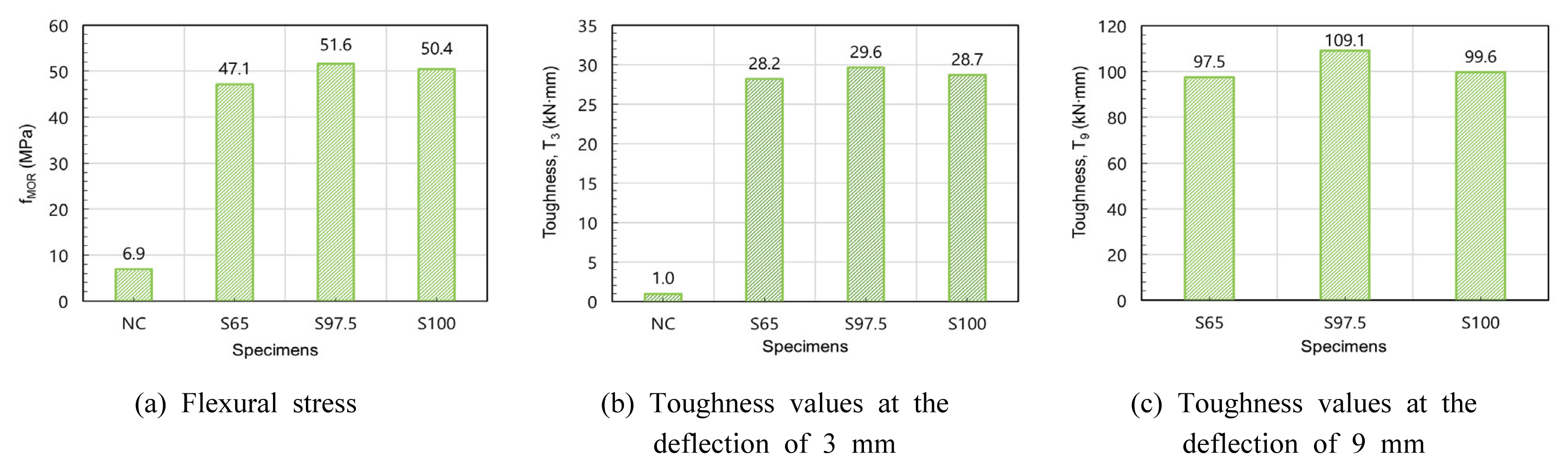

Fig. 12Ùèö ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ýâüýÿ¿(Ambient)ýùÉýä£ýØÿ Ý£¿ ýä▒ÙèÑýØä ÝÅëÛ░ÇÝòÿÛ©░ ý£äÝò£ ÙïñýûæÝò£ ýºÇÝæ£ÙÑ╝ ÙéÿÝâÇÙé©Ùïñ. Ý£¿ Û░òÙÅäÙèö f=PL/bd2ýÖÇ Û░ÖýØ┤ Û│äýé░ÙÉÿýùêý£╝Ù®░, ýù¼Û©░ýä£ fÙèö Ý£¿ Û░òÙÅä, PÙèö ýáüýÜ® Ýòÿýñæ, bÙèö ýïñÝùÿý▓┤ýØÿ ÝÅ¡, dÙèö ýïñÝùÿý▓┤ýØÿ ÙåÆýØ┤ÙÑ╝ ÙéÿÝâÇÙé©Ùïñ. ýùÉÙäêýºÇ ýåîýé░ÙèÑÙáÑýØÇ toughnessÙÑ╝ ýØ┤ýÜ®Ýò┤ýä£ ÝÅëÛ░Ç ÙÉÿýùêý£╝Ù®░, toughnessÙèö Ýòÿýñæ-Ù│Çý£ä Ý£¿ Û│íýäáýùÉýä£ Ýè╣ýáò Ù│Çý£ä(3 mm, 9 mm)Û╣îýºÇýØÿ Ù®┤ýáüý£╝Ùí£ Û│äýé░ÙÉÿýùêÙïñ.

S65 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ ÝÅëÛÀá Ý£¿ Û░òÙÅäÙèö 39.4 MPaÙí£ ÙéÿÝâÇÙé¼ý£╝Ù®░, S97.5 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ ÝÅëÛÀá Ý£¿ Û░òÙÅäÙèö 50.4 MPaÙí£, S100 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ Ý£¿ Û░òÙÅäÙèö 54.9 MPaÙí£ ÙéÿÝâÇÙé¼ý£╝Ù®░, ýØ┤Ùƒ¼Ýò£ Û░ÆÙôñýØÇ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ÝÅëÛÀá Ý£¿ Û░òÙÅäýØ© 8.0 MPaýÖÇ Ù╣äÛÁÉÝòá Ùòî ýò¢ 5Ù░░, 6Ù░░, 7Ù░░ Ýü░ Û░Æý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ.

ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ 3 mm Ù│Çý£äÛ╣îýºÇýØÿ toughness Û░ÆýØÇ 1.5 KNÔïàmmÙí£ Û│äýé░ÙÉÿýùêý£╝Ù®░, S65 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ toughness Û░ÆýØÇ ýä¼ý£á ýóàÙÑÿ Ù│äÙí£ Û░üÛ░ü26.9, 29.4, 31.5 KNÔïàmmÙí£ Û│äýé░ÙÉÿýùêÙïñ. UHPCÛ░Ç ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©Ù│┤Ùïñ ÙºñýÜ░ ýÜ░ýêÿÝò£ ýùÉÙäêýºÇ ýåîýé░ÙèÑÙáÑýØä Û░ûÙèö Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêý£╝Ù®░, Ý£¿ Û░òÙÅäýÖÇ Û░ÖýØ┤ UHPCýØÿ Û░òýä¼ý£áýØÿ ÝÿòýâüÙ╣äÛ░Ç ý╗ñýºÉýùÉ Ùö░ÙØ╝ ýùÉÙäêýºÇ ýåîýé░ÙèÑÙáÑ ÙÿÉÝò£ ýªØÛ░ÇÝòÿÙèö Û▓âýØä ÝÖòýØ©ÝòÿýÿÇÙïñ. ýä¼ý£á ýóàÙÑÿýùÉ Ùö░ÙÑ© UHPCýØÿ 9 mm Ù│Çý£äÛ╣îýºÇýØÿ toughness Û░ÆýØÇ Û░üÛ░ü 80.3, 105.7, 106.1 KNÔïàmmÙí£ Û│äýé░ÙÉÿýùêý£╝Ù®░, ýØ┤ ÙÿÉÝò£ Ý£¿ Û░òÙÅä Ù░Å 3 mm Ù│Çý£äÛ╣îýºÇýØÿ toughness Û░ÆÛ│╝ Û░ÖýØÇ Û▓¢ÝûÑýØä ÙéÿÝâÇÙâêÙïñ.

Fig. 13ýØÇ ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä(Cryogenic-AC) Ý£¿ ýä▒ÙèÑ ýºÇÝæ£ÙÑ╝ ÙéÿÝâÇÙé©Ùïñ. ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤ÝøäýùÉÙÅä UHPCÙèö ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©Ù│┤Ùïñ ÙºñýÜ░ ÙåÆýØÇ Ý£¿ ýä▒ÙèÑýØä ÙéÿÝâÇÙé┤Ùèö Û▓âýØ┤ ÝÖòýØ©ÙÉÿýùêÙïñ.

ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û▓¢ýÜ░ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä Ý£¿ Û░òÙÅäÙèö 6.9 MPaÙí£ ýâüýÿ¿ýùÉýä£ýØÿ Ý£¿ Û░òÙÅäýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ýò¢ 13% Û░ÉýåîÝò£ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ. ÙÿÉÝò£ 3 mm Ù│Çý£äýùÉýä£ýØÿ toughness Û░ÆýØÇ 1.0 KNÔïàmmÙí£ ýâüýÿ¿ýùÉýä£ýØÿ Û░ÆÛ│╝ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ýò¢ 33% Û░ÉýåîÝò£ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ. ýØ┤Ùƒ¼Ýò£ Û▓░Û│╝Ùèö ýò×ýä£ ÛÀáýù┤Û▒░ÙÅÖýùÉýä£ ÝÖòýØ©Ýò£ Ù░öýÖÇ Û░ÖýØ┤ ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýò£ Ýæ£Ù®┤ýØÿ ÛÀáýù┤ ýâØýä▒ Ùô▒ýØÿ ýåÉýâüýØ┤ Ù░£ýâØÝòÿýÿÇÛ©░ ÙòîÙ¼©ýØ┤Ùïñ.

ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Û▓¢ýÜ░ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ýâüýÿ¿ýùÉýä£ýØÿ Ý£¿ ýä▒ÙèÑ ýºÇÝæ£ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî S65 ýï£ÝÄ©ýØÿ Ý£¿ Û░òÙÅäÙèö ýò¢ 20% ÝûÑýâüÙÉÿýùêý£╝Ù®░, S97.5 ýï£ÝÄ©ýØÿ Ý£¿ Û░òÙÅäÙèö ýò¢ 2% ÝûÑýâüÙÉÿýùêÛ│á, S100 ýï£ÝÄ©ýØÿ Ý£¿ Û░òÙÅäÙèö ýò¢ 8% Û░ÉýåîÝòÿýÿÇÙïñ. Ýè╣Ý×ê ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýò£ ýåÉýâüý£╝Ùí£ S100 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ Ý£¿ ýä▒ÙèÑýØ┤ S97.5 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ Ý£¿ ýä▒ÙèÑ Ù│┤Ùïñ ý×æÛ▓î ý©íýáòÙÉ£ Û▓âýØä ÝÖòýØ©ÝòÿýÿÇÙïñ. Û▓îÙïñÛ░Ç S65 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ UHPCýØÿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ý×ÉÛ©░ý╣ÿý£áÙí£ ýØ©Ýò£ Ý£¿ ýä▒ÙèÑ ÝûÑýâüÛ│╝ Ùº×Ù¼╝Ùáñ 9 mmýùÉýä£ýØÿ toughness Û░ÆýØÇ S65 ýï£ÝÄ©Û│╝ Ýü░ ý░¿ýØ┤ÙÑ╝ Ù│┤ýØ┤ýºÇ ýòèýòÿÙïñ. ýØ┤Ùƒ¼Ýò£ Û▓░Û│╝Ùèö ýò×ýä£ ýû©Û©ëÝò£ Ù░öýÖÇ Û░ÖýØ┤ ýé¼ýáäýùÉ ý£áÙÅäÙÉ£ Ù»©ýä©ÛÀáýù┤ ÝÅ¡ýùÉ Ùö░ÙÑ© ý×ÉÛ©░ý╣ÿý£á Û▒░ÙÅÖ Ù░Å ýåÉýâü ýáòÙÅäýØÿ ý░¿ýØ┤Ùí£ ýØ©Ýò£ Û▓âýØ┤Ù®░, ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýùÉ ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýò£ ýåÉýâüýØ┤ Ù░£ýâØ Ýòá ýï£ýùÉÙèö S97.5 ýä¼ý£á ÙÿÉÙèö S65 ýä¼ý£áÙÑ╝ ýé¼ýÜ®ÝòÿÙèö Û▓âýØ┤ Ý£¿ ýä▒ÙèÑ ÝÖòÙ│┤ýùÉ ý£áÙª¼Ýò£ ýáÉýØä ÝÖòýØ©Ýòá ýêÿ ý×êýùêÙïñ.

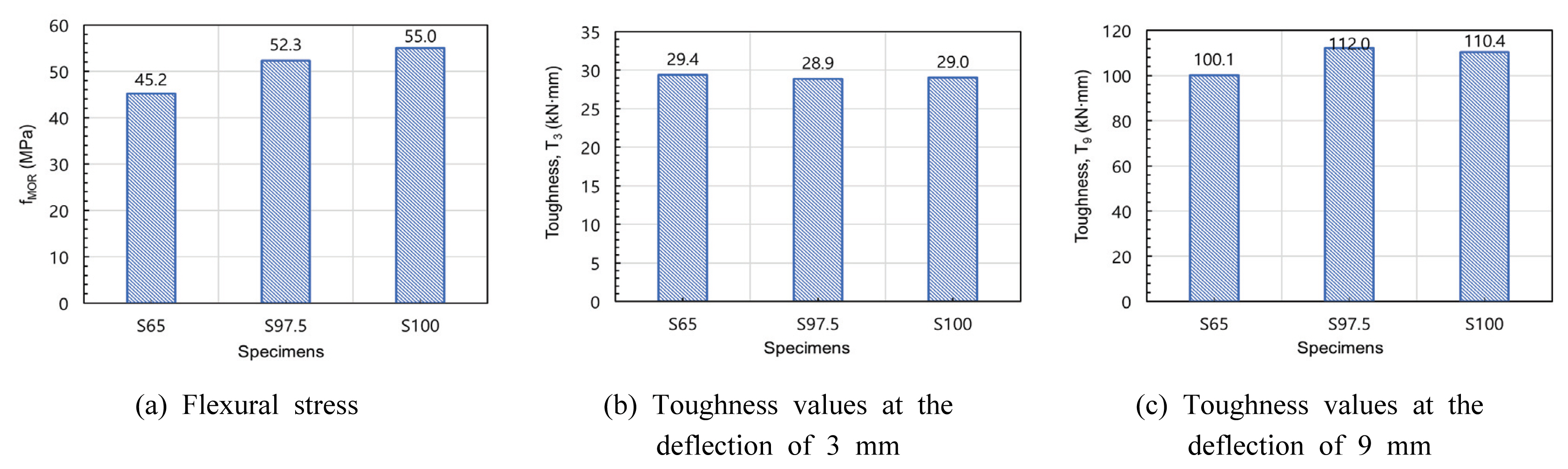

Fig. 14Ùèö ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä 28ýØ╝ýØÿ ýêÿýñæýûæýâØ(Cryogenic-WC)ýùÉ Ùö░ÙÑ© Ý£¿ ýä▒ÙèÑ ýºÇÝæ£ÙÑ╝ ÙéÿÝâÇÙé©Ùïñ. ýâüýÿ¿ýùÉýä£ýØÿ Ý£¿ ýä▒ÙèÑÛ│╝ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä 28ýØ╝ýØÿ ýêÿýñæýûæýâØýØä ýïñýï£Ýò£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ Ý£¿ ýä▒ÙèÑýØÇ ýä¼ý£á ýóàÙÑÿýùÉ Û┤ÇÛ│äýùåýØ┤ Ù¬¿ÙæÉ ÝÜîÙ│Á Ýÿ╣ýØÇ ÝûÑýâüÙÉ£ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ. S65 ýä¼ý£áÙÑ╝ ýé¼ýÜ®ÝòÿýÿÇýØä Ùòî Ý£¿Û░òÙÅäÙèö ýò¢ 15% ýªØÛ░ÇÝòÿýÿÇý£╝Ù®░, S97.5 ýä¼ý£áÙÑ╝ ýé¼ýÜ®ÝòÿýÿÇýØä ÙòîÙèö ýò¢ 4% ýªØÛ░ÇÝòÿýÿÇÛ│á, S100 ýä¼ý£áÙÑ╝ ýé¼ýÜ®ÝòÿýÿÇýØä ÙòîÙèö Û©░ýí┤ ýâüýÿ¿ýØÿ Ý£¿ Û░òÙÅäÙÑ╝ ýÖäýáäÝ×ê ÝÜîÙ│ÁÝòÿýÿÇÙïñ. Ùö░ÙØ╝ýä£ 28ýØ╝ýØÿ ýêÿýñæýûæýâØýØä ÝåÁÝò┤ ý┤êýáÇýÿ¿ Ùà©ý£Ùí£ ýØ©Ýò£ Ý£¿ ýä▒ÙèÑýØÿ ýåÉýâüýØä ÝÜîÙ│ÁÝòá ýêÿ ý×êÙèö Û▓âýØä ÝÖòýØ©ÝòÿýÿÇÙïñ.

Ù│© ýù░ÛÁ¼ýùÉýä£Ùèö ýÁ£ÛÀ╝ ýáòÙÂÇýØÿ ýùÉÙäêýºÇýáäÝÖÿ ýáòý▒à Ùô▒ý£╝Ùí£ ýØ©Ýò£ ýòíÝÖöý▓£ýù░Û░ÇýèñýØÿ ýêÿýÜö ýªØÛ░ÇÛ░Ç ýÿêýâüÙÉ¿ýùÉ Ùö░ÙØ╝ Ùêäý£ýé¼Û│á Ù░£ýâØ ýï£ ýé¼ÝÜîý×¼Ùé£ ýé¼Û│áÙí£ ýù░Û▓░ÙÉá ýêÿ ý×êÙèö LNG ýáÇý×ÑÝâ▒Ýü¼ýØÿ ýòêýáäýä▒ýØä ÝûÑýâüýï£ÝéñÛ©░ ý£äÝò┤ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ÙÑ╝ ýÖ©ýí░ ÛÁ¼ýí░Ù¼╝ýùÉ ýáüýÜ®ýï£ÝéñÛ©░ ý£äÝò£ ýù░ÛÁ¼ÙÑ╝ ýºäÝûëÝòÿýÿÇÙïñ.

ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© Ý£¿ Û▒░ÙÅÖ Ù░Å ÛÀáýù┤Û▒░ÙÅÖ, ý×ÉÛ©░ý╣ÿý£á Û▒░ÙÅÖýØä ÝÅëÛ░ÇÝòÿýÿÇý£╝Ù®░, ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ÙîÇýí░ÛÁ░ý£╝Ùí£ýì¿ Ýÿäý×¼ Ýò£ÛÁ¡Û░ÇýèñÛ│Áýé¼ýùÉýä£ ýÖ©ýí░ýØÿ Û▒┤ýäñý×¼ÙúîÙí£ ýáüýÜ®ÙÉÿÛ│áý×êÙèö Ù░░Ýò®ýØä ýé¼ýÜ®ÝòÿýÿÇÙïñ. ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýä© ýóàÙÑÿ(S65, S97.5, S100)ýØÿ Û░òýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýòÿýù¼ Û░òýä¼ý£áýØÿ ýóàÙÑÿýùÉ Ùö░ÙÑ© ýÿüÝûÑýØä ÝÅëÛ░ÇÝòÿýÿÇÙïñ. ýØ┤ÙÑ╝ ý£äÝò┤ 4ýáÉ Ý£¿ ýïñÝùÿ Ù░Å ý┤êýáÇýÿ¿ Ùà©ý£ ýïñÝùÿ, Û┤æÝòÖ ÝÿäÙ»©Û▓¢ Û┤Çý░░, SEM-EDX ÙÂäýäØýØä ýêÿÝûëÝòÿýÿÇý£╝Ù®░, ýú╝ýÜö ýù░ÛÁ¼Û▓░Û│╝Ùèö ÙïñýØîÛ│╝ Û░ÖÙïñ.

(1) ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýùÉ ÙïñýêÿýØÿ Ù»©ýä©ÛÀáýù┤ýØä ÝÖòýØ©ÝòÿýÿÇý£╝Ùéÿ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýùÉýä£Ùèö ýû┤ÙûáÝò£ Û▓░Ýò¿ Ù░Å ÛÀáýù┤ýØ┤ Ù░£ýâØÝòÿýºÇ ýòèýòÿÙïñ. Ùö░ÙØ╝ýä£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýØ╝Ù░ÿý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ý┤êýáÇýÿ¿ Ùà©ý£ýùÉ Ùö░ÙÑ© ÛÀáýù┤ýùÉ ÙåÆýØÇ ýáÇÝò¡ýä▒ÙèÑýØä Û░ûÙèö Û▓âýØä ÝÖòýØ©ÝòÿýÿÇÙïñ.

(2) ýä© ýóàÙÑÿýØÿ Û░òýä¼ý£á ýñæ S65 ýä¼ý£áÛ░Ç ýé¼ýÜ®ÙÉ£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýùÉýä£ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ýâüýÿ¿ýùÉýä£ ýÿ¿ÙÅäÙÑ╝ ÝÜîÙ│ÁÝò¿ýùÉ Ùö░ÙØ╝ Ù░£ýâØÝòÿÙèö Ù¼╝Ùí£ ýØ©Ýò£ ÛÀáýù┤ ÝÅ¡ Û░Éýåî ÝÿäýâüýØä ÝÖòýØ©ÝòÿýÿÇÙïñ.

(3) SEM-EDX ÙÂäýäØýØä ÝåÁÝò┤ 12.2 ÒÄøýØÿ Ù»©ýä©ÛÀáýù┤Û│╝ 62.1 ÒÄø Ù»©ýä©ÛÀáýù┤ýØ┤ ý▒äýøîýºÇÙèö Û©░Û░äýØÇ Û░üÛ░ü 7ýØ╝, 28ýØ╝Ùí£ ÝÖòýØ©ÙÉÿýùêý£╝Ù®░, 12.2 ÒÄøýØÿ ýóüýØÇ Ù»©ýä©ÛÀáýù┤ýØÇ ý┤êÛ©░ 1ýØ╝ý░¿ýùÉ ÛÀáýù┤ýØ┤ Ù╣áÙÑ┤Û▓î ý▒äýøîýºÇÙèö Û▓âýØä ÝÖòýØ©ÝòÿýÿÇÙïñ. ÙÿÉÝò£ EDX ýøÉýåîÙÂäýäØýØä ÝåÁÝò┤ ÛÀáýù┤ý▒äýøÇ Ù¼╝ýºêýØÇ Ýâäýé░ý╣╝ýèÿ(CaCO3)ý×äýØä ÝÖòýØ©ÝòÿýÿÇÙïñ.

(4) ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö ýØ╝Ù░ÿ ý¢ÿÝü¼Ùª¼Ýè©ýÖÇ Ù╣äÛÁÉÝòÿýÿÇýØä Ùòî ý┤êýáÇýÿ¿ Ùà©ý£Û│╝ Û┤ÇÛ│äýùåýØ┤ ýÁ£ÙîÇ ýò¢ 7Ù░░ ÙåÆýØÇ Ý£¿ Û░òÙÅäÙÑ╝ Ù│┤ýØ┤Ù®░, ýùÉÙäêýºÇ ýåîýé░ÙèÑÙáÑ ÙÿÉÝò£ ÙºñýÜ░ Ùø░ýû┤Ùé£ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêÙïñ.

(5) S100 ýä¼ý£áÛ░Ç ýé¼ýÜ®ÙÉ£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©Ùèö 2ý░¿ ý┤êýáÇýÿ¿ Ùà©ý£ ýØ┤Ýøä ýä▒ÙèÑ Û░ÉýåîÝÅ¡ýØ┤ Û░Çý×Ñ Ýü░ Û▓âý£╝Ùí£ ÝÖòýØ©ÙÉÿýùêý£╝Ù®░, 28ýØ╝ýØÿ ýêÿýñæýûæýâØýØä ÝåÁÝò┤ Ù¬¿Ùôá ýóàÙÑÿýØÿ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ýØÿ ýä▒ÙèÑýØ┤ ÝÜîÙ│Á ÙÿÉÙèö ÝûÑýâüÙÉ£ Û▓âýØä ÝÖòýØ©ÝòÿýÿÇÙïñ.

(6) Ùö░ÙØ╝ýä£ LNG ýáÇý×ÑÝâ▒Ýü¼ýØÿ ýÖ©ýí░ýùÉ S65 ýä¼ý£áÙÑ╝ ýé¼ýÜ®Ýò£ ý┤êÛ│áýä▒ÙèÑ ý¢ÿÝü¼Ùª¼Ýè©ÙÑ╝ ýáüýÜ®Ýòá ýï£ýùÉ Ùø░ýû┤Ùé£ ýù¡ÝòÖýáü ýä▒ÙèÑ Ù░Å ý×ÉÛ©░ý╣ÿý£á Ýè╣ýä▒ý£╝Ùí£ ýØ©Ýò£ ýòêýáòýä▒ Ù░Å Ùé┤ÛÁ¼ýä▒ýØä Ýü¼Û▓î ÝûÑýâüýï£Ýé¼ýêÿ ý×êýØä Û▓âý£╝Ùí£ ÝîÉÙï¿ÙÉ£Ùïñ.

Fig. 6

The Microscopic Images of Microcracks on UHPC After 2nd Cryogenic Exposure at Magnification of x500

Fig. 10

SEM Images Used and Results of EDX Analysis of Newly Formed Particles After 28 Days of Water Curing

Table 1

Mixture Proportions

Table 2

Physicalnd Geometrical Properties of Straight Steel Fibers a

Table 3

Chemical Comositions and Physical Properties of Cementitious Materials

References

ASTM /C1609M (2012). Standard test method for flexural performance of fiber-reinforced concrete (Using beam with third-point loading). ASTM International, West Conshohocken, PA: p 1-9.

Aydin, S, Yazici, H, Yardimci, MY, and Yigiter, H (2010) Effect of aggregate type on mechanical properties of reactive powder concrete. ACI Mater J, Vol. 107, No. 5, pp. 441-449.

Chan, YN, Luo, X, and Sun, W (2000) Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800┬░C. Cem Concr Res, Vol. 30, No. 2, pp. 247-251.

Dahmani, L, Khenane, A, and Kaci, S (2007) Behavior of the reinforced concrete at cryogenic temperatures. Cryogenics, Vol. 47, No. 9, pp. 517-525.

Edvardsen, C (1999) Water permeability and autogeneous healing of cracks in concrete. ACI Mater J, Vol. 96, No. 4, pp. 448-454.

Homma, D, Mihashi, H, and Nishiwaki, T (2009) Self-healing capability of fibre reinforced cementitious composites. J Adv Concr Technol, Vol. 7, No. 2, pp. 217-228.

Jacobsen, S, and Sellevold, EJ (1996) Self healing of high strength concrete after deterioration by freeze/thaw. Cem Concr Res, Vol. 26, No. 1, pp. 55-62.

Jamshidi, R, Lake, C, Gunning, P, and Hills, C (2016) Effect of freeze/thaw cycles on the performance and microstructure of cement-treated soils. J Mater Civil Eng, Vol. 28, No. 16, pp. 04016162.

Kim, MJ, Yoo, DY, Kim, S, Shin, M, and Bantia, N (2018) Effects of fiber geometry and cryogenic condition on mechanical properties of ultra-high-performance fiber-reinforced concrete. Cem Concr Res, Vol. 107, pp. 30-40.

Kogbara, RB, Iyengar, SR, Grasley, ZC, Masad, EA, and Zollinger, DG (2013) A review of concrete properties at cryogenic temperatures: Towards direct LNG containment. Constr Build Mater, Vol. 47, pp. 760-770.

Kwon, S, Nishiwaki, T, Kikuta, T, and Mihashi, H (2013). Experimental study on self-healing capability of 15 cracked ultra-high-performance hybrid-fiber-reinforced cementitious composites. 3rd International 16 Conference on Sustainable Construction Materials and Technologies. Kyoto, Japan.

McHenry, D, and Brewer, HW (1945) Discussion of a paper by T. C. Powers: A working hypothesis for further studies of frost resistance of concrete. Journal of the ACI, Vol. 41, pp. 272. pp. 9-12.

Orgass, M, and Klug, Y (2004). Fibre reinforced ultra-high strength concretes. Proceedings of the 1st International Symposium on Ultra High Performance Concrete. Kassel, Germany: pp. 637-647.

Richard, P, and Cheyrezy, M (1995) Composition of reactive powder concretes. Cem Concr Res, Vol. 25, No. 7, pp. 1501-1511.

Rostásy, FS, Schneider, U, and Wiedemann, G (1979) Behaviour of mortar and concrete at extremely low temperatures. Cem Concr Res, Vol. 9, No. 3, pp. 365-376.

Rostásy, FS, Weiß, R, and Wiedemann, G (1980) Changes of pore structure of cement mortars due to temperature. Cem Concr Res, Vol. 10, No. 2, pp. 157-164.

Rougeau, P, and Borys, B (2004). Ultra high performance concrete with ultrafine particles other than silica fume. Proceedings of the International Symposium on Ultra High Performance Concrete. Kassel, Germany: pp. 213-225.

Talaiekhozan, A, Keyvanfar, A, Shafaghat, A, Andalib, R, Abd Majid, MZ, Fulazzaky, MA, et al (2014) A review of self-healing concrete research development. J Environ Treat Tech, Vol. 2, No. 1, pp. 1-11.

Teichmann, T, and Schmidt, M (2004). Influence of the packing density of fine particles on structure, strength and durability of UHPC. Proceedings of the International Symposium on Ultra High Performance Concrete. Kassel, Germany: pp. 313-323.

Tongaroonsri, S, and Tangtermsirikul, S (2008) Influence of mixture condition and moisture on tensile strain capacity of concrete. ScienceAsia, Vol. 34, No. 1, pp. 59-68.

Yoo, DY, Banthia, N, Yang, JM, and Yoon, YS (2016) Size effect in normal- and high-strength amorphous metallic and steel fiber reinforced concrete beams. Constr Build Mater, Vol. 121, pp. 676-685.

Yoo, DY, Kang, ST, Lee, JH, and Yoon, YS (2013) Effect of shrinkage reducing admixture on tensile and flexural behaviors of UHPFRC considering fiber distribution characteristics. Cem Concr Res, Vol. 54, pp. 180-190.

- TOOLS

-

METRICS

-

- 2 Crossref

- 3,706 View

- 83 Download

- Related articles in KOSHAM

-

Applications of Artificial Neural Networks for Using High Performance Concrete2003 December;3(4)